Intelligent Integrated Automated Line

about //

Yongkang Hubang

Machinery Technology Co., Ltd.

Hubang is committed to technological R&D, driving innovation to continuously improve product performance. Let us join hands and create a brighter future together.

Company founded in

Patent certificate

Annual output value

advantage //

Smart Automation for Cup & Pot Production

Intelligent Integrated Automated Production Line

Intelligent Integrated Automated Production Line

It primarily integrates traditional craftsmanship and consolidates all thermos cup production processes into a single equipment, achieving automation in the most compact size.

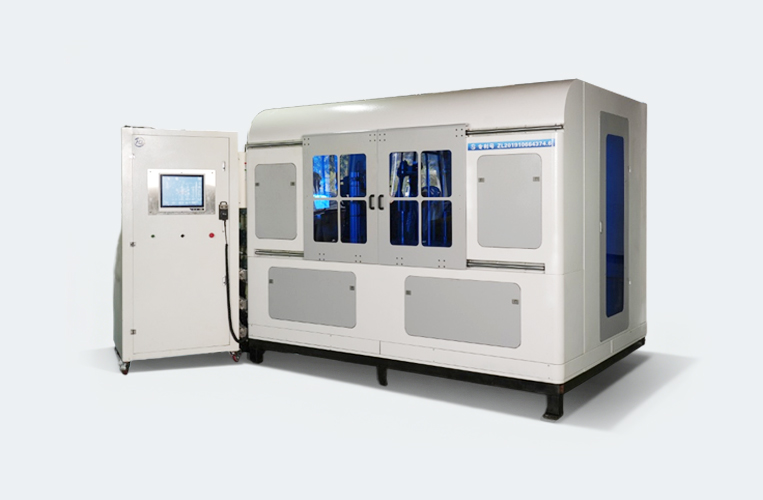

Multi-functional Rotary Automatic Polishing Machine

Multi-functional Rotary Automatic Polishing Machine

Precision positioning, achieves exact process polishing based on different polishing requirements for various cup parts.

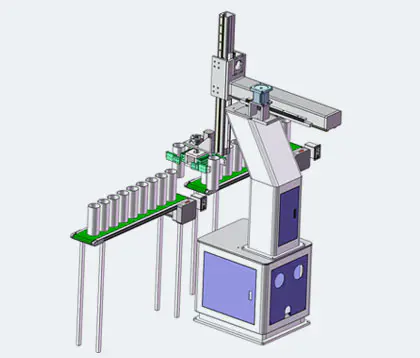

The Mechanical Hand Is Automatically Started With One Click

The Mechanical Hand Is Automatically Started With One Click

Upgrade to fully automated production lines utilizing existing equipment—no professional needed, ordinary workers can operate with one-touch startup.

Reliable Support and Service

The Production Process Is A Seamless Operation

The function of tube cutting is to precisely cut long stainless steel raw material tubes into individual tube blanks according to the preset length of the cup outer shell, providing the blanks for subsequent processing steps.

It involves using specialized rolling tools to curl, shape, and finish the edge of one end of the cup body (typically the future opening) to meet the final design requirements.

It uses ultra-high-pressure water as the power medium to expand and form straight or irregularly shaped tube blanks into complex profiles (such as drum, gourd, or curved shapes) that meet the design requirements.

It reduces the diameter of one end of the cup body (typically the top opening) through localized compression, forming a specific stepped or tapered structure.

It reduces the diameter of one end of the cup body (typically the top opening) through localized compression, forming a specific stepped or tapered structure.

It excises the excess portions (i.e., scrap ends) generated during previous processing that do not conform to the product's final dimensional requirements, resulting in a cup body with precise dimensions and neat edges.

It involves processes like spinning, rolling, or grinding to make the shoulder curve of the cup body smooth, consistent in shape, and dimensionally precise, thereby ensuring perfect fit with the lid and overall aesthetic appeal.

It involves the machining, flattening, and smoothing of the welded base to ensure it conforms to the designed shape, dimensional accuracy, and flatness requirements, allowing the cup to stand stably and meet aesthetic standards.

It roll-forms precisely mated threads onto the cup opening and the lid (or lid retainer) to achieve reliable screwing and sealing between the lid and the cup body.

This involves machining both the opening and the base of the cup body to achieve a flat, smooth finish that is perpendicular to the central axis, thereby ensuring the product's core functionality and quality.

It uses roll-forming to create a comfortable, ergonomic bevel on the rim of the cup opening, thereby enhancing the drinking experience.

The Automatic Polishing Machine for Stainless Steel Bottles is specially designed for the surface polishing of cup and pot bodies, providing a high-quality finish and consistent results. Key Features ...

Intelligent Integrated Automated Line

The CNC Pipe Cutting Machine is designed for high-precision cutting of stainless steel pipes, especially suited for cup ...

The CNC Rim Neck Cutting Machine is a high-precision, fully automated equipment designed for cutting and trimming the wa...

The 24-Station Water-Cooled Temperature Measuring Machine is designed for accurate and efficient temperature testing of ...

We are proud to announce the official launch of the website for Yongkang Hubang Machinery Technolog...