We are proud to announce the official launch of the website for Yongkang Hubang Machinery Technology Co., Ltd.!

READ MORE-

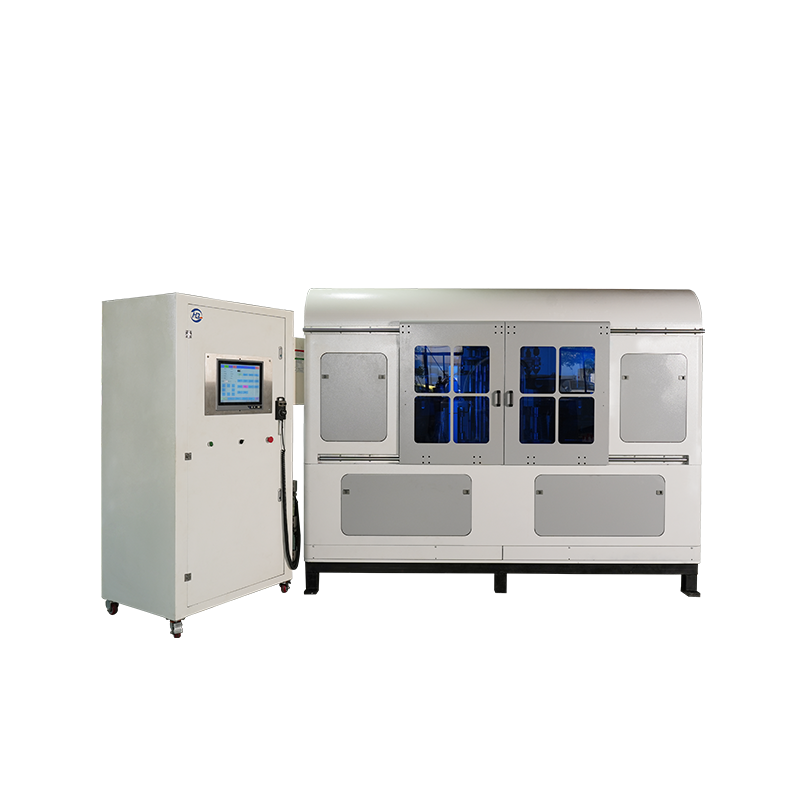

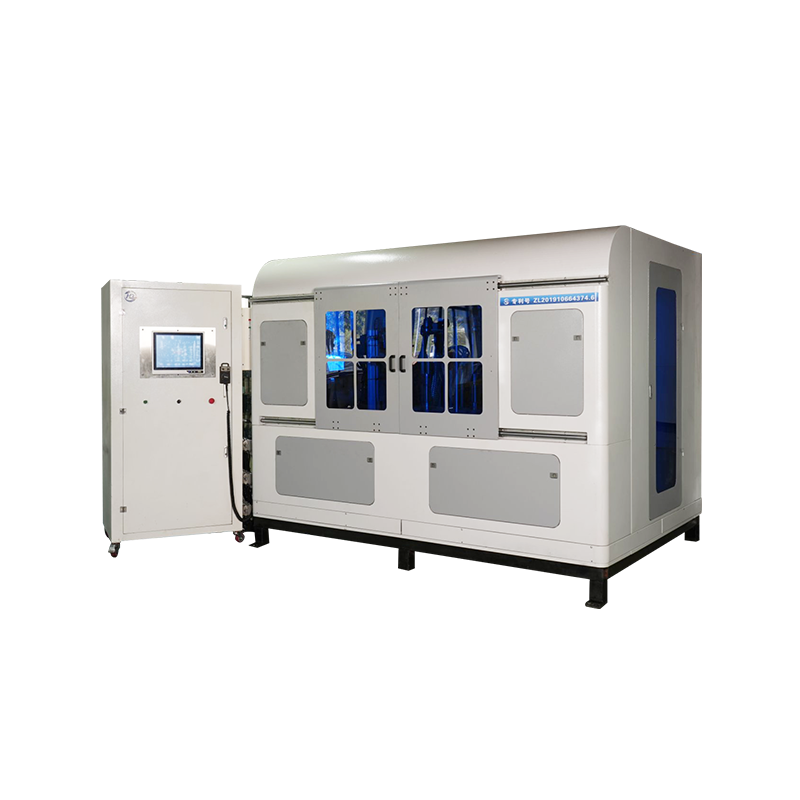

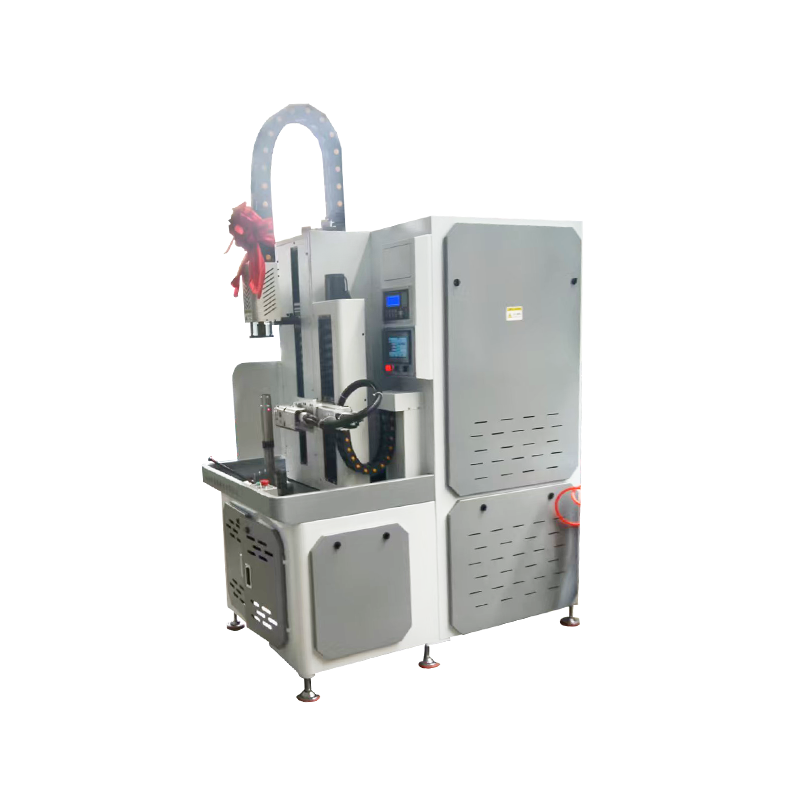

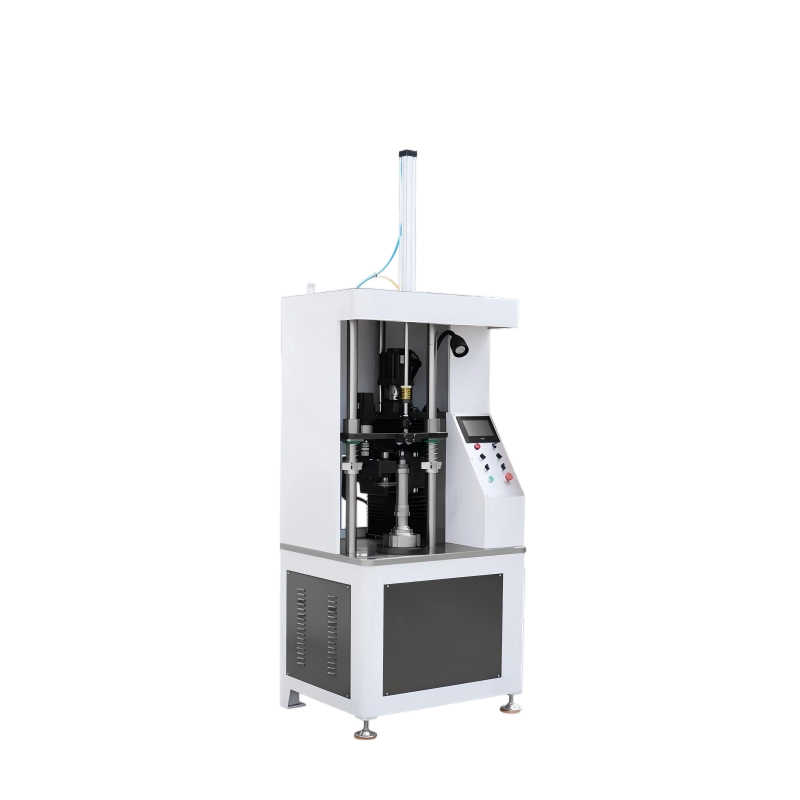

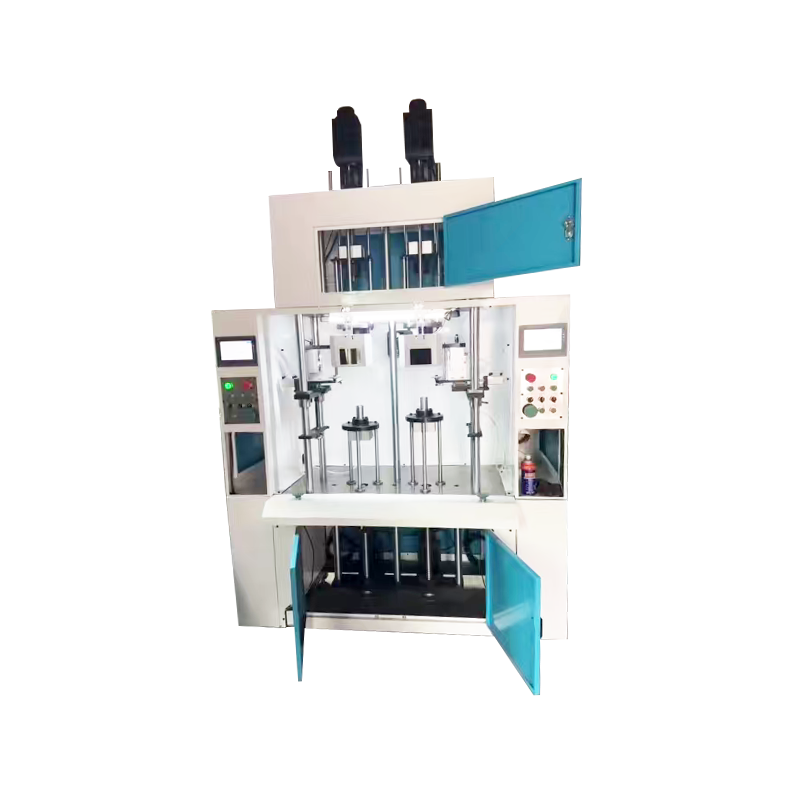

The Automatic Polishing Machine for Stainless Steel Bottles is specially designed for the surface polishing of cup and pot bodies, providing a high-quality finish and consistent results.

Key Features and Advantages:

Advanced Control System: Equipped with an industrial computer control system, the machine ensures stable performance, simple operation, and fast learning curve. Operators can master basic functions within 10 minutes.

Efficient Work Table Design: The double-station work table allows for simultaneous processing of multiple parts, significantly improving production efficiency. It supports both rotary and single-station polishing modes.

Flexible Polishing Options: Changing polishing materials or fixtures is straightforward, enabling quick adaptation to different product specifications. This flexibility makes the machine suitable for a wide range of stainless steel bottle sizes and shapes.

Robust Construction: The main chassis is cast from high-quality cast iron, featuring an integrated structure with excellent rigidity and seismic resistance.

Ease of Maintenance and Operation: The machine’s design emphasizes ease of use, from simple fixture changes to quick adjustment of polishing materials, reducing downtime and enhancing overall workflow.

-

Specifications (Mpa)

Hydraulic(Min)

Productivity(KW)

Rated power(Kg)

Net weight(MM)

Overall dimensions0.5-0.8 8 7.0 3500 2356×1656×2100 -

Polishing

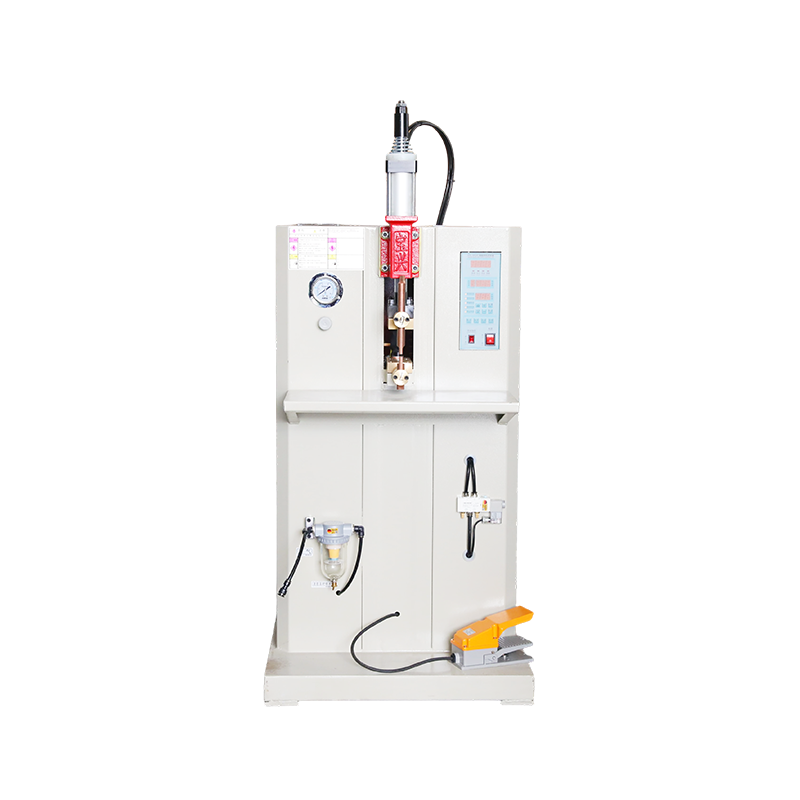

It employs mechanical or electrochemical means to remove imperfections such as scratches, oxide layers, and welding discoloration from the stainless steel cup body. This process imparts the desired gloss, texture, and feel, ultimately enhancing the product's aesthetic grade, cleanability, and user experience.

English

English