We are proud to announce the official launch of the website for Yongkang Hubang Machinery Technology Co., Ltd.!

READ MORE-

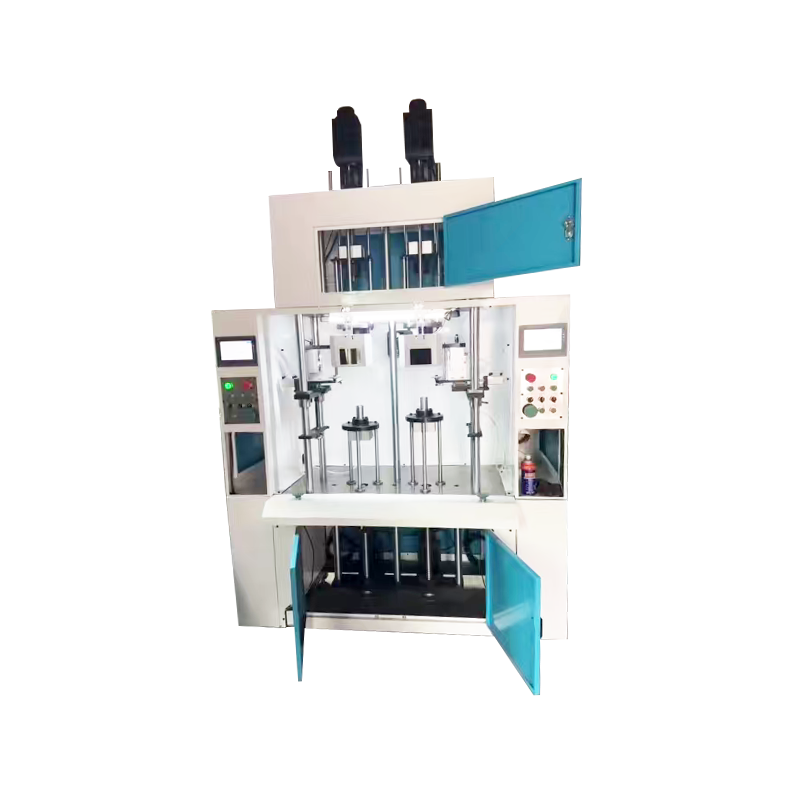

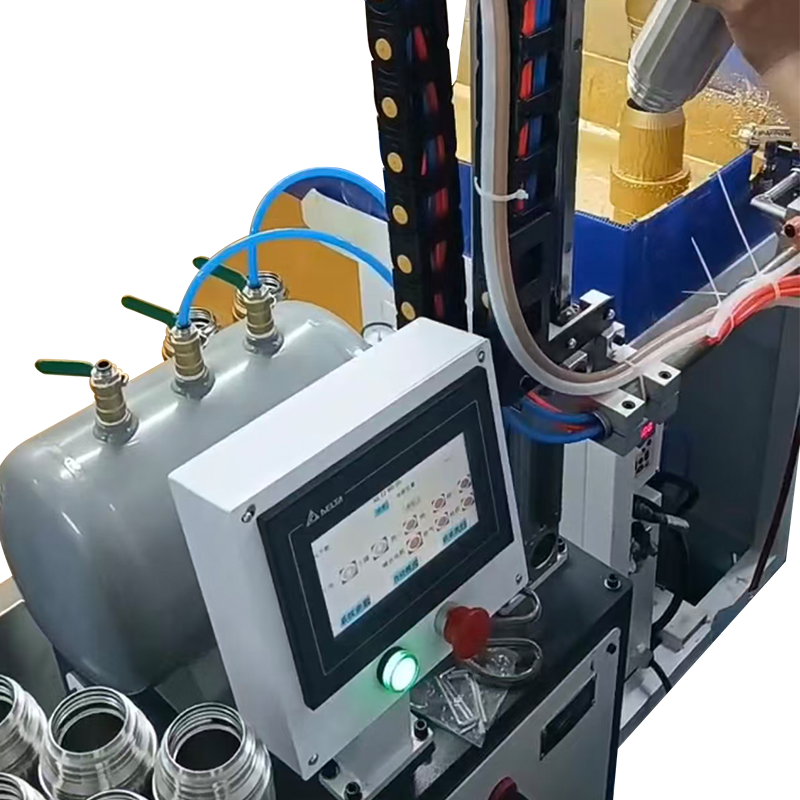

The Auto 2 Stations Laser Flask Inner Welding Machine is made for welding of cup and pot bodies with flat or short arc bottoms. This equipment is suitable for large-scale production of stainless steel vacuum flasks, thermal cups, and similar containers.

Product Features:

PLC Integrated Control: The machine adopts a PLC-based control system for stable operation, intelligent parameter setting, and convenient control interface.

High Automation: It supports manual loading and unloading combined with automatic welding, pressing, and sealing, significantly reducing labor intensity.

Double-Station Worktable: The dual-station rotary design allows continuous production—one station can operate while the other is loaded—effectively increasing productivity.

Simple Fixture Design: The fixture is easy to clamp and adjust, ensuring high positioning accuracy and operator convenience.

Smooth Spindle Drive: A stepper motor with a reducer drives the spindle rotation, providing smooth and adjustable speed for consistent welding quality.

Stable Welding Performance: The laser welding process ensures firm joints, uniform weld seams, and excellent sealing, suitable for various metal materials and flask types.

-

Specifications (Mpa)

Hydraulic(Min)

Productivity(KW)

Rated power(Kg)

Net weight(MM)

Overall dimensions0.4-0.6 12 0.6 350 1150×1000×2250 -

English

English