We are proud to announce the official launch of the website for Yongkang Hubang Machinery Technology Co., Ltd.!

READ MORE-

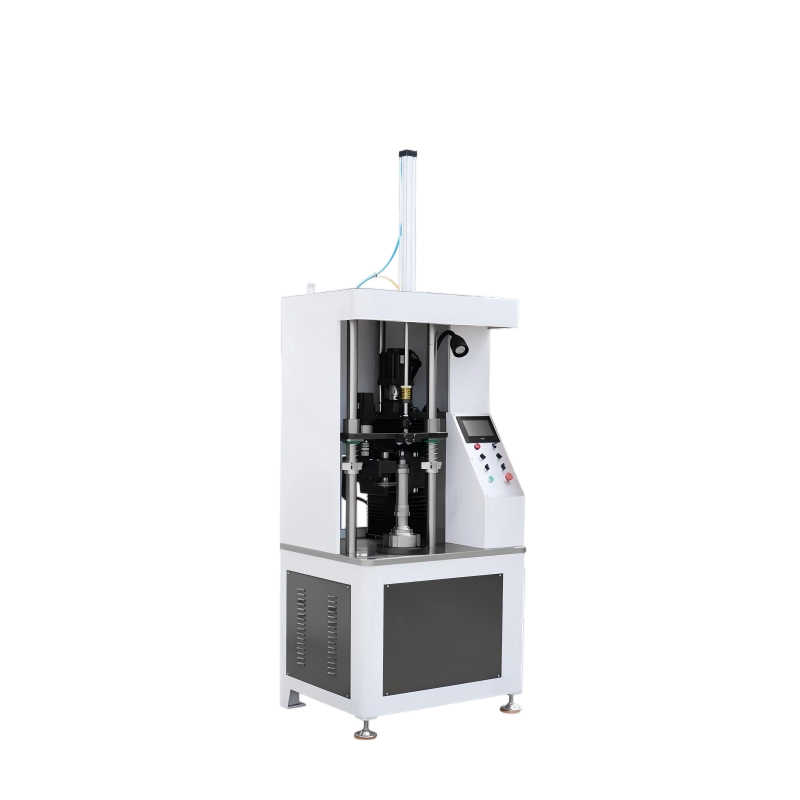

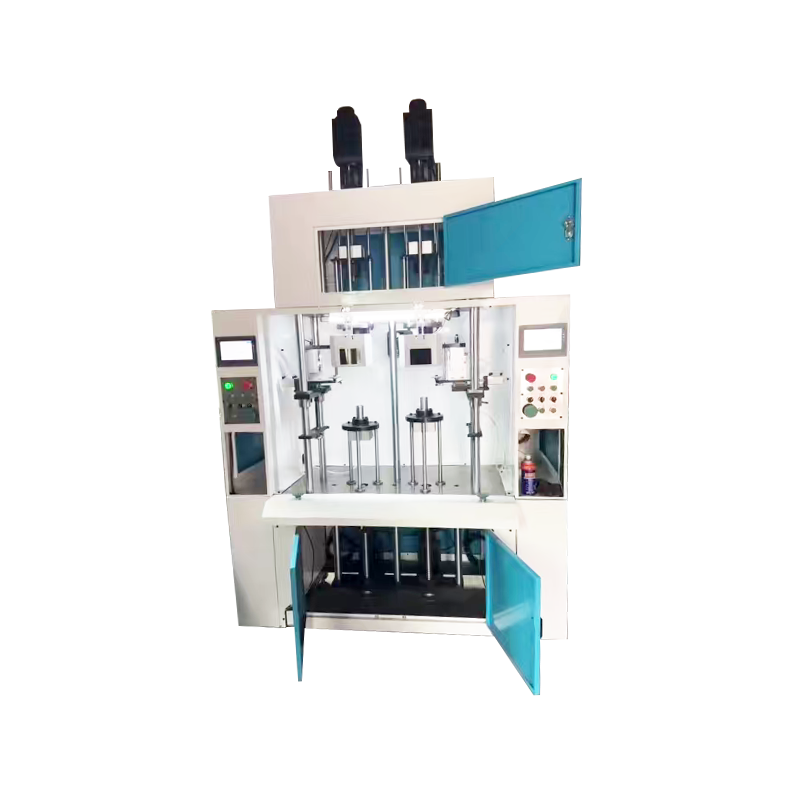

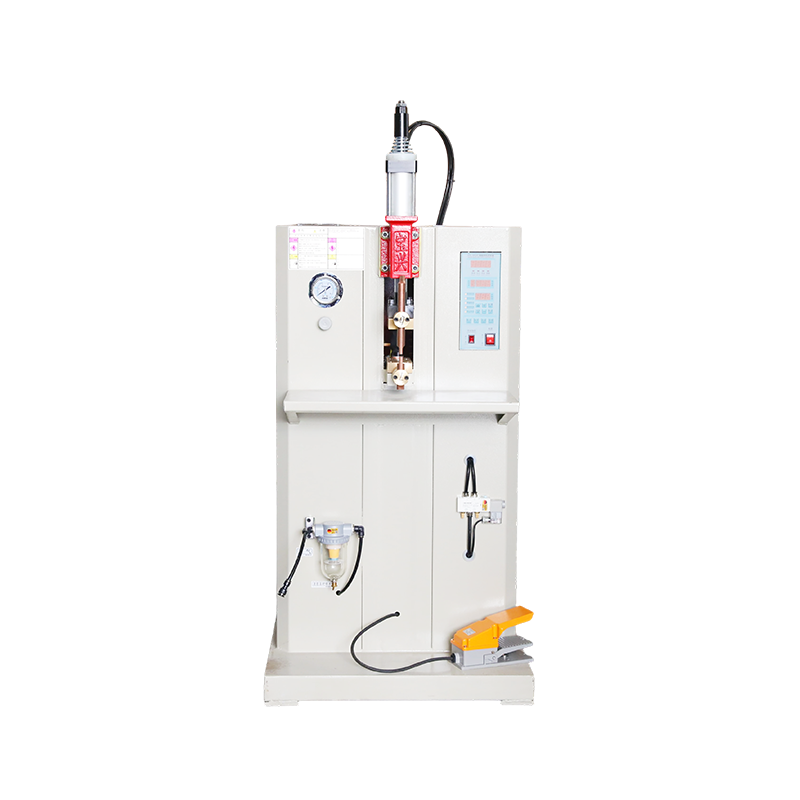

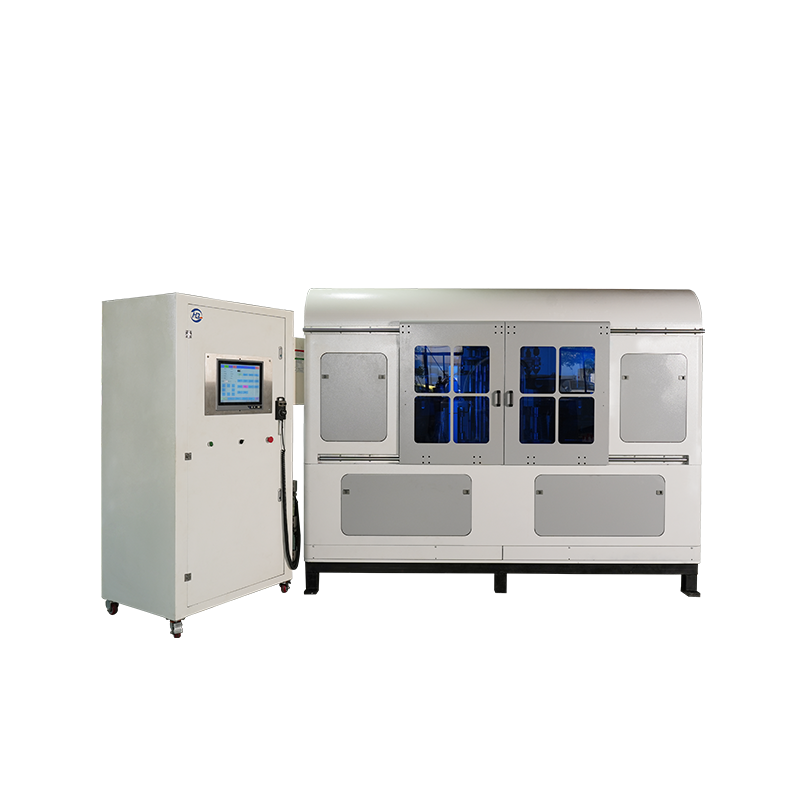

The Hydraulic Welding Seam Flatten Rolling Machine is a specialized piece of equipment designed for rolling and leveling the welding seam in the welding area of metal pipes, ensuring a smooth and even surface for subsequent processing.

Main Features:

User-Friendly Operation: Equipped with a clear button and knob interface, operators can easily control rolling pressure, direction, and position, ensuring smooth and safe operation.

Adjustable Propulsion Position: The front and rear propulsion positions can be precisely adjusted to accommodate different pipe lengths and seam locations, improving flexibility in use.

Hydraulic Control System: Features a selected hydraulic station with dual cylinders that move up and down smoothly. The hydraulic system provides stable and adjustable pressure, maintaining consistent performance under continuous operation.

High-Strength Mold Shaft: The mold shaft is made from Cr12 steel and undergoes vacuum quenching to achieve a hardness of HRC62°, ensuring excellent wear resistance and long service life.

Durable Frame Construction: The main chassis is firmly welded and fixed with A3 steel plates and screws, offering high structural stability and vibration resistance during operation.

-

Specifications (Mpa)

Hydraulic(Min)

Productivity(KW)

Rated power(Kg)

Net weight(MM)

Overall dimensions2-4 16 2.2 195 920×1120×1300 -

English

English