We are proud to announce the official launch of the website for Yongkang Hubang Machinery Technology Co., Ltd.!

READ MORE-

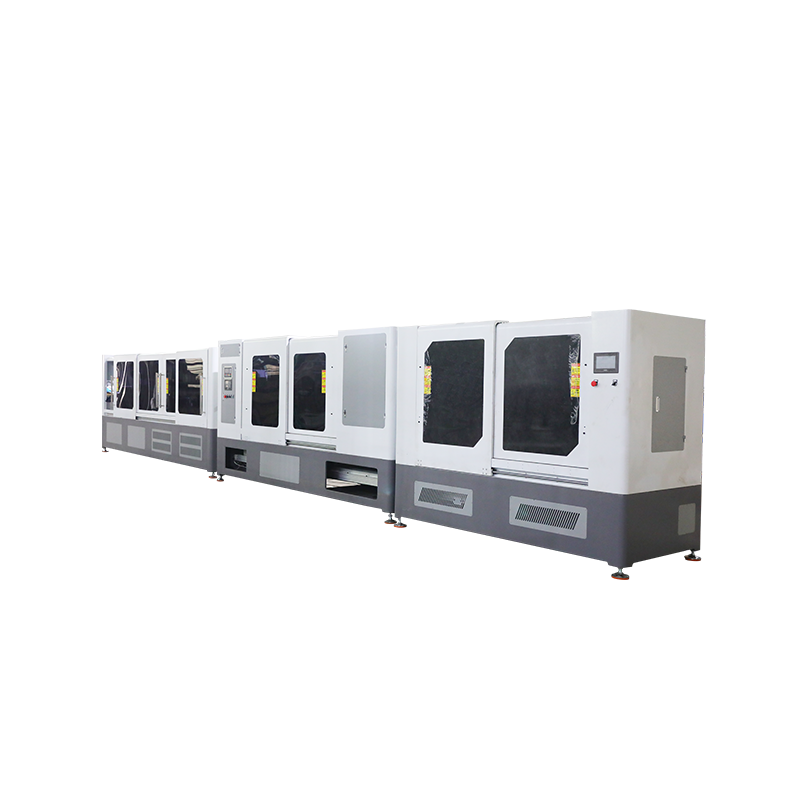

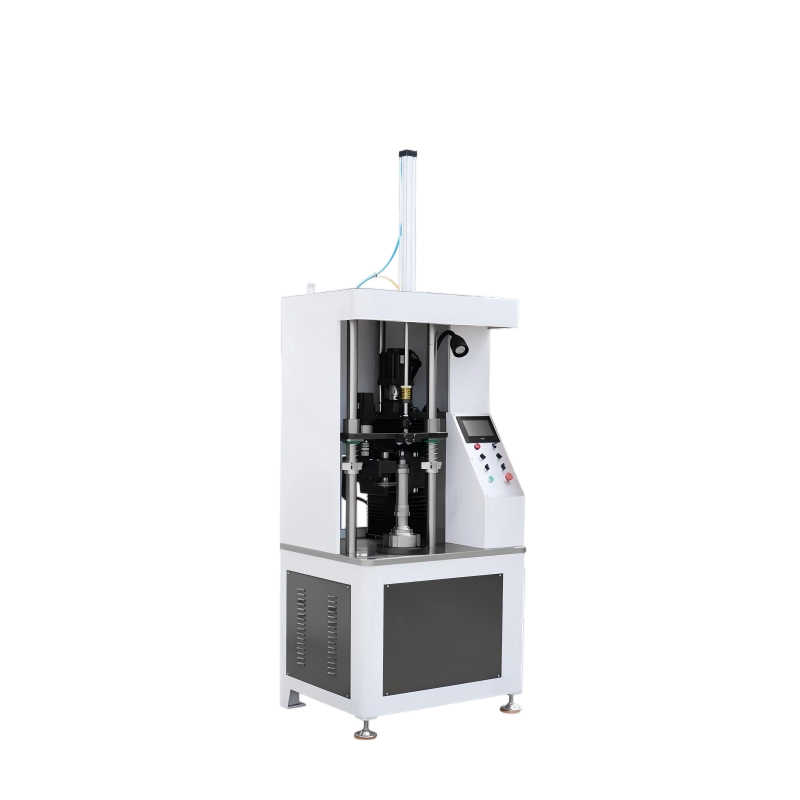

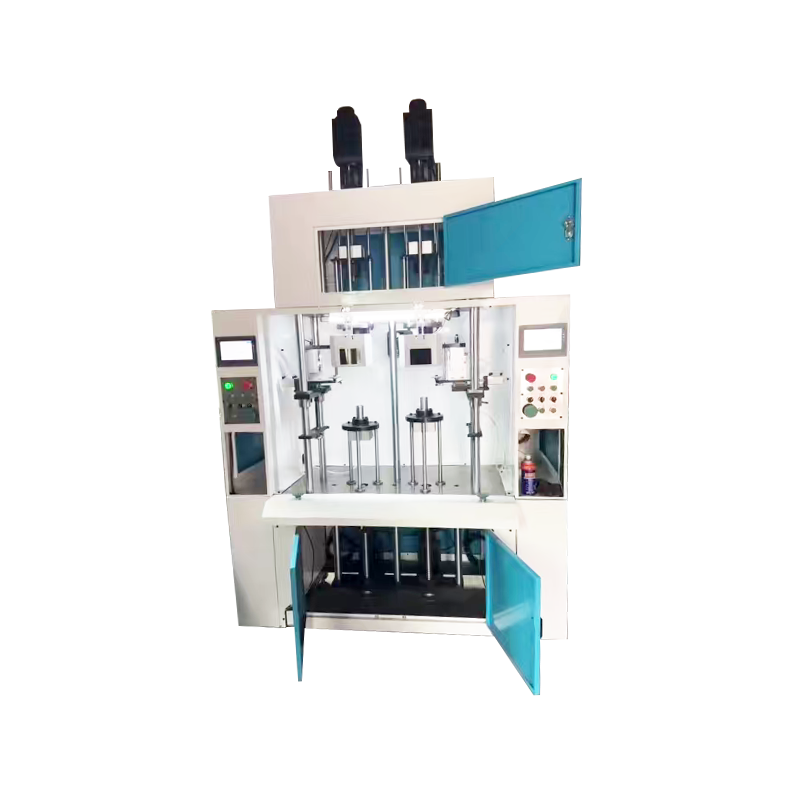

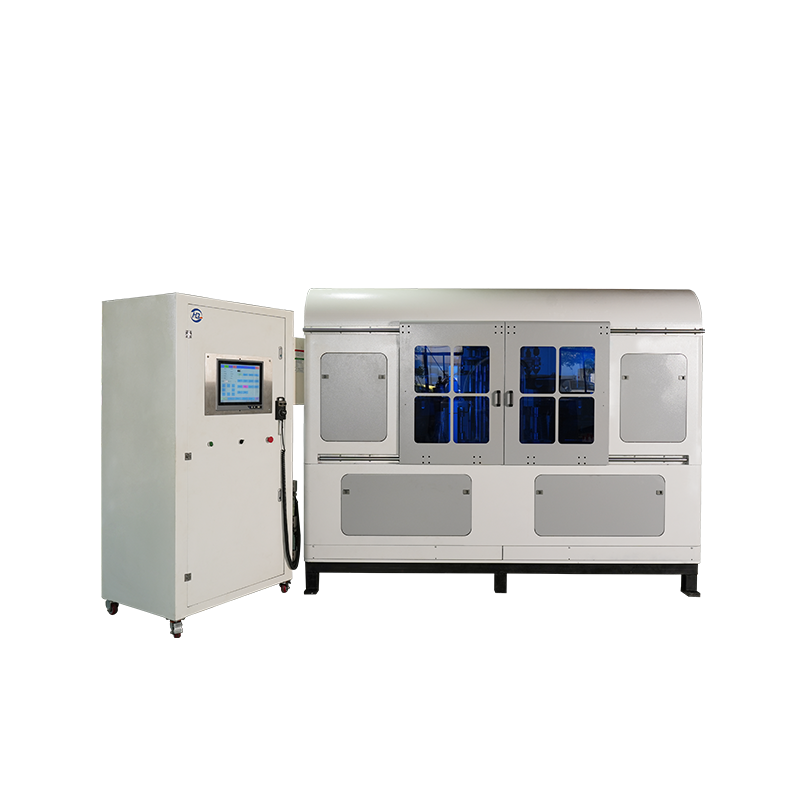

The Automatic Ultrasonic Cleaning Machine is designed for efficient and precise cleaning of stainless steel (SS) bottles and containers. It provides comprehensive cleaning of both the inner and outer surfaces, ensuring high cleanliness standards required in industries such as food, beverage, and pharmaceutical manufacturing.

Key Features:

High-Quality Material: The cleaning tank is made of imported stainless steel with excellent acid and alkali resistance, ensuring long service life and corrosion protection.

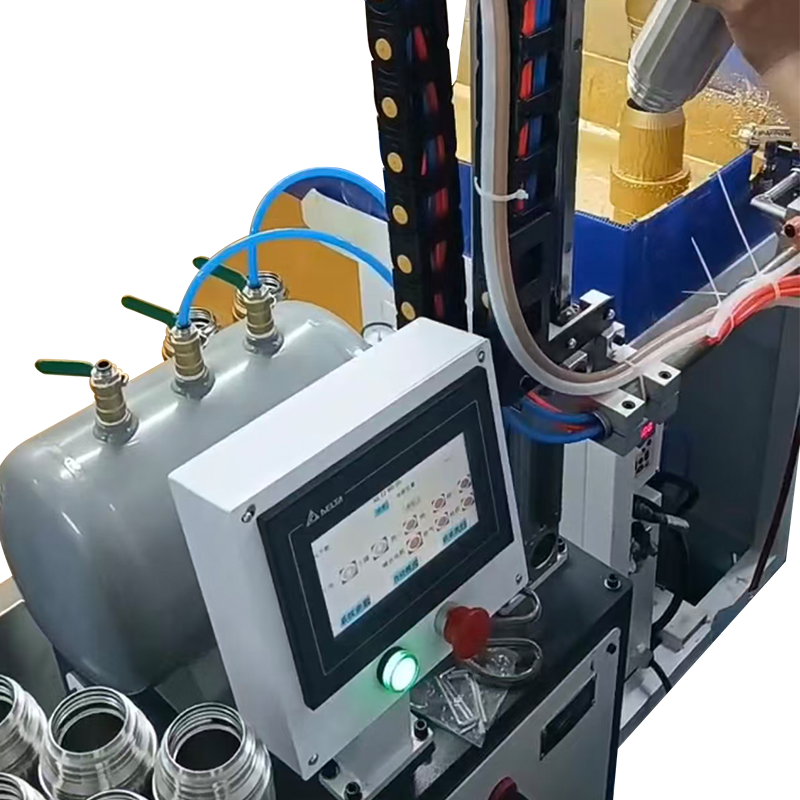

Advanced Ultrasonic Technology: Equipped with a powerful ultrasonic output system using high Q-value transducers and a unique ultrasonic generator, providing strong cavitation and deep cleaning performance.

Temperature Control System: Integrated automatic temperature control heating device, adjustable from room temperature to 100°C, maintaining optimal cleaning efficiency.

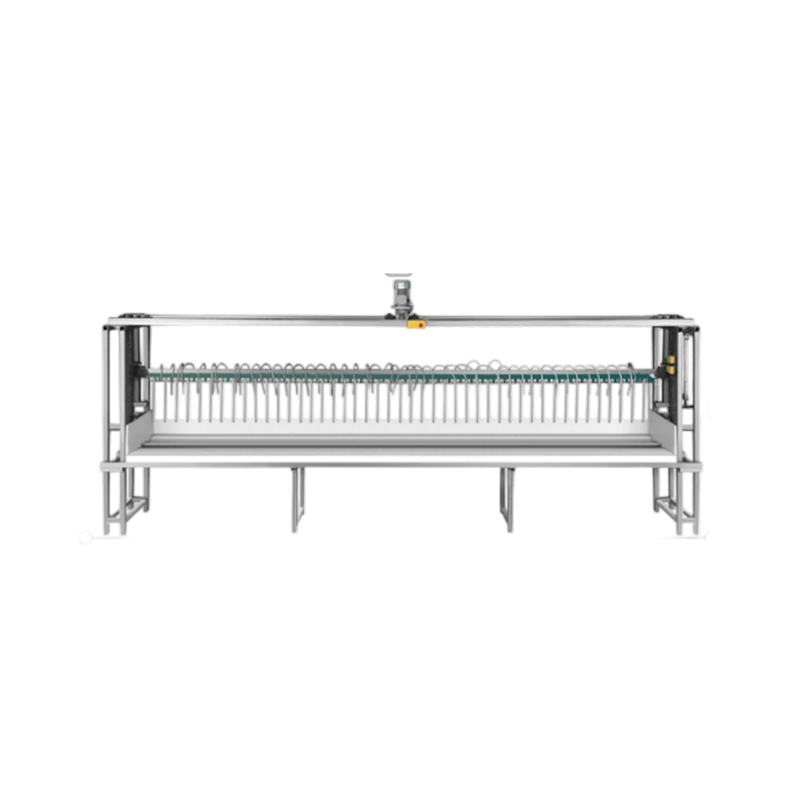

Multi-Tank Cleaning Process: The system includes multiple rinsing tanks with constant temperature devices, allowing continuous cleaning and rinsing in one complete cycle.

Circulating Drying System: Equipped with a high-efficiency circulating air drying system that quickly removes moisture from products after cleaning, ensuring they are ready for the next production stage.

Process Flow:

Feeding → Hot Alkali Spray Cleaning → Primary Spray Rinsing → Secondary Spray Rinsing → Triple Spray Rinsing → Fan Blowing → Discharging -

Specifications (Min)

Productivity(KW)

Hating power(KW)

UItrasonic power(MM)

Slot sizeNumber of slots 800 1x10-1 40 550x535x685 Multi-trough -

English

English