We are proud to announce the official launch of the website for Yongkang Hubang Machinery Technology Co., Ltd.!

READ MORE-

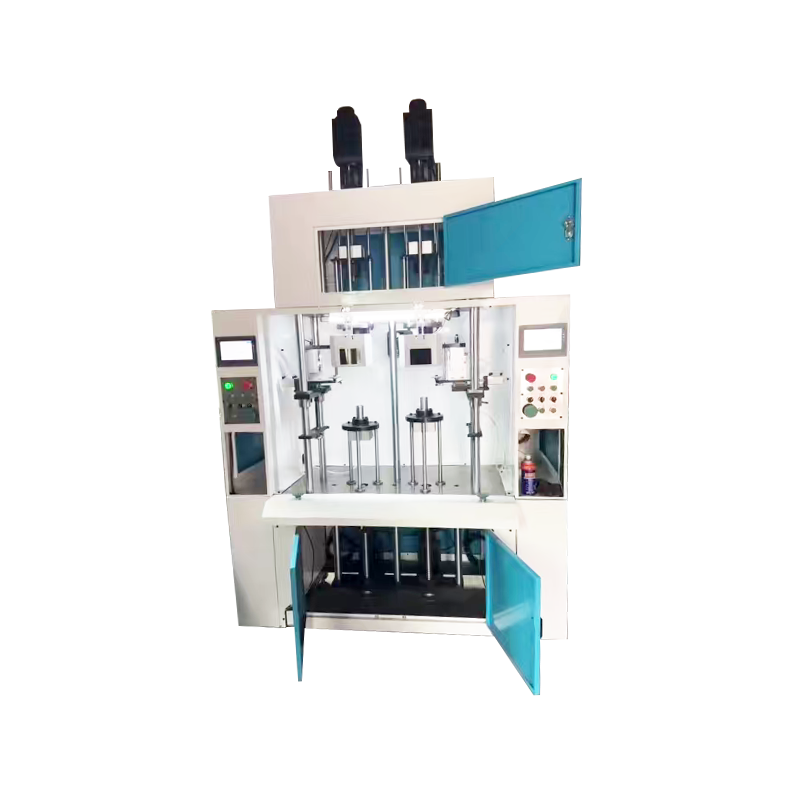

The Laser Bottle Flask Dividing Machine is designed for precision processing of various cup and pot components, including division, cutting edges, flat mouths, flat bottoms, and anti-cup operations.

Key Features:

Advanced Control System:

Equipped with a PLC and touch screen control system, the machine provides intuitive operation, stable performance, and flexible process adjustment.Four-Axis Linkage:

The X and Z axes move vertically, the Y-axis spindle rotates, and the C-axis uses an upper cylinder vacuum system. This ensures smooth motion coordination, fast cutting speed, and high precision in every process.Adaptive Height Adjustment:

The machine includes a height adjuster that controls X-axis servo motor propulsion, compensating for irregularities or deformation in cups and pots.Clean and Efficient Cutting:

Automatic suction ensures no dust remains inside the cup body, keeping the internal surface clean. The laser-cut sections are smooth, flat, and free of burrs, providing excellent surface quality.Versatile Application:

Suitable for general-purpose processing, including head cutting, flat mouth and bottom shaping, and cup splitting, making it ideal for manufacturers of stainless steel and insulated bottle products. -

Specifications (Mpa)

Hydraulic(Mpa)

Cutting air pressure(Min)

Productivity(KW)

Rated power(Kg)

Net weight(MM)

Overall dimensions0.5-0.8 1.0-1.5 12 4.0 874 1100×1500×2350 -

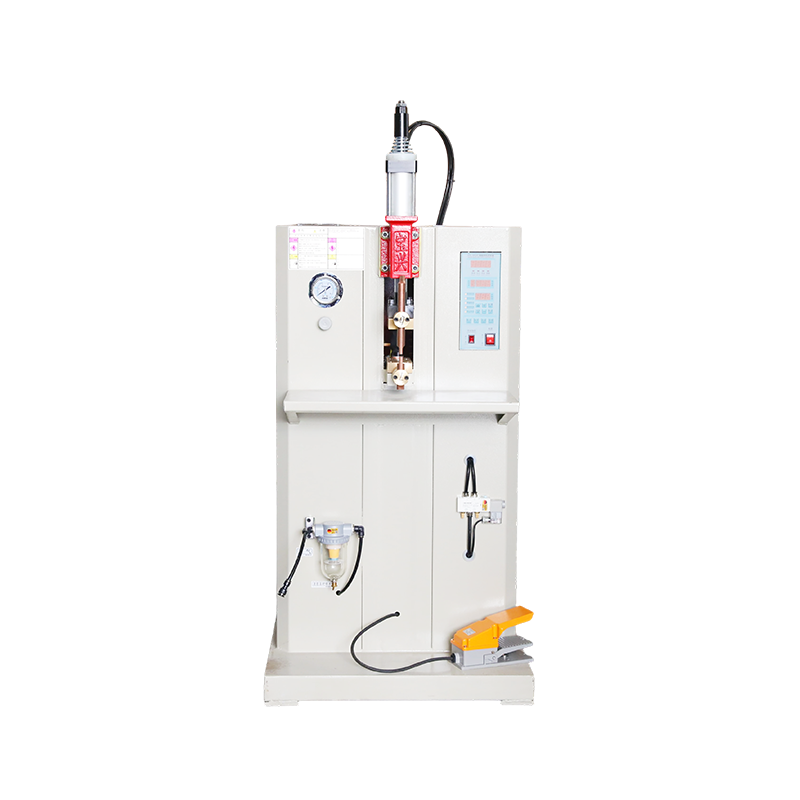

Water Rise

It uses ultra-high-pressure water as the power medium to expand and form straight or irregularly shaped tube blanks into complex profiles (such as drum, gourd, or curved shapes) that meet the design requirements.

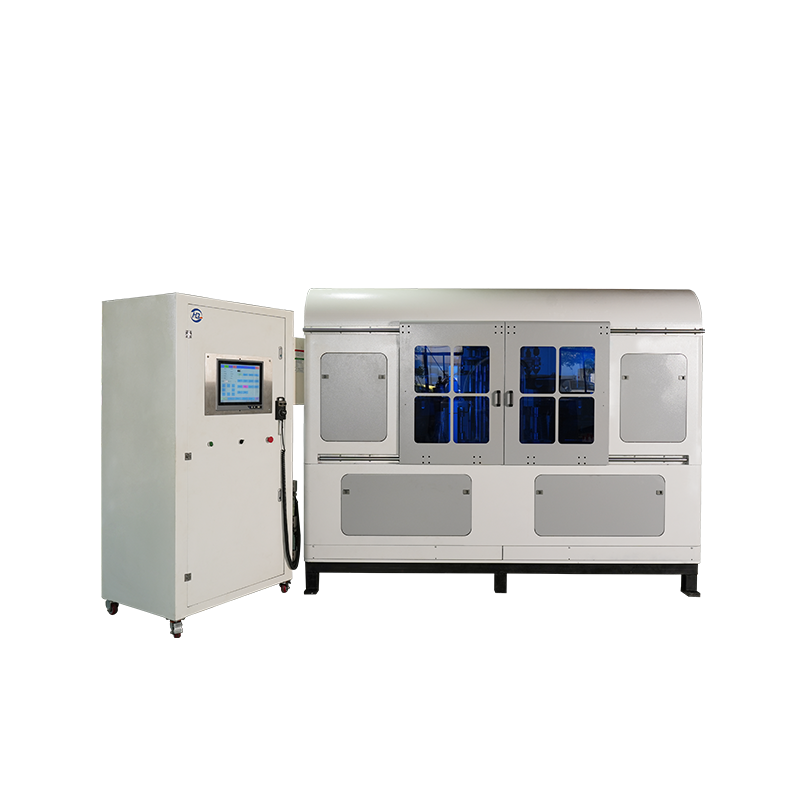

SegmentationIt involves cutting a long, semi-finished inner liner tube blank (e.g., after thinning) into two or shorter liners, thereby significantly improving material utilization and production efficiency.

English

English