We are proud to announce the official launch of the website for Yongkang Hubang Machinery Technology Co., Ltd.!

READ MORE-

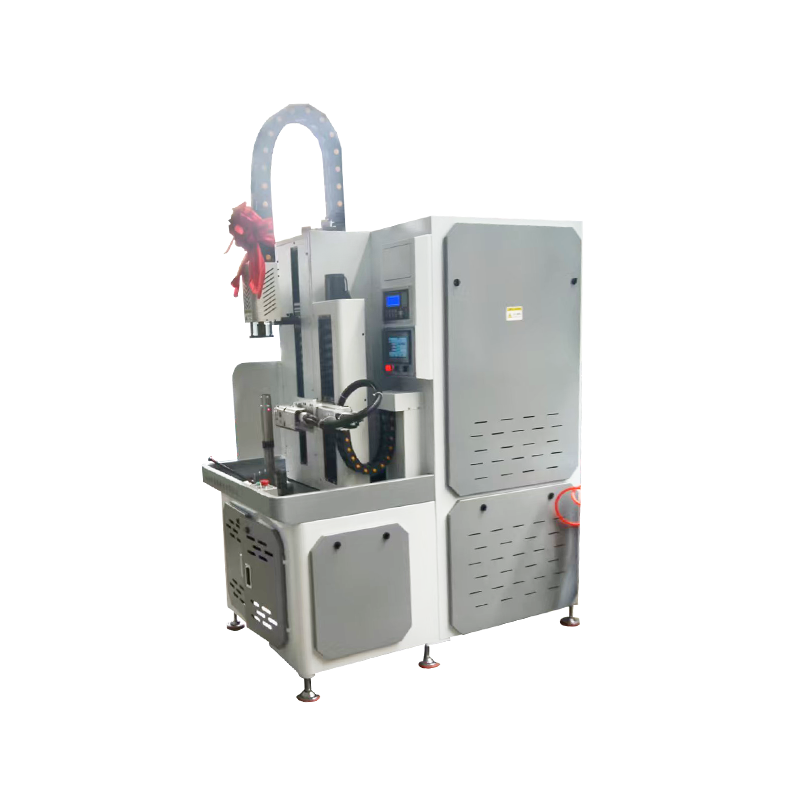

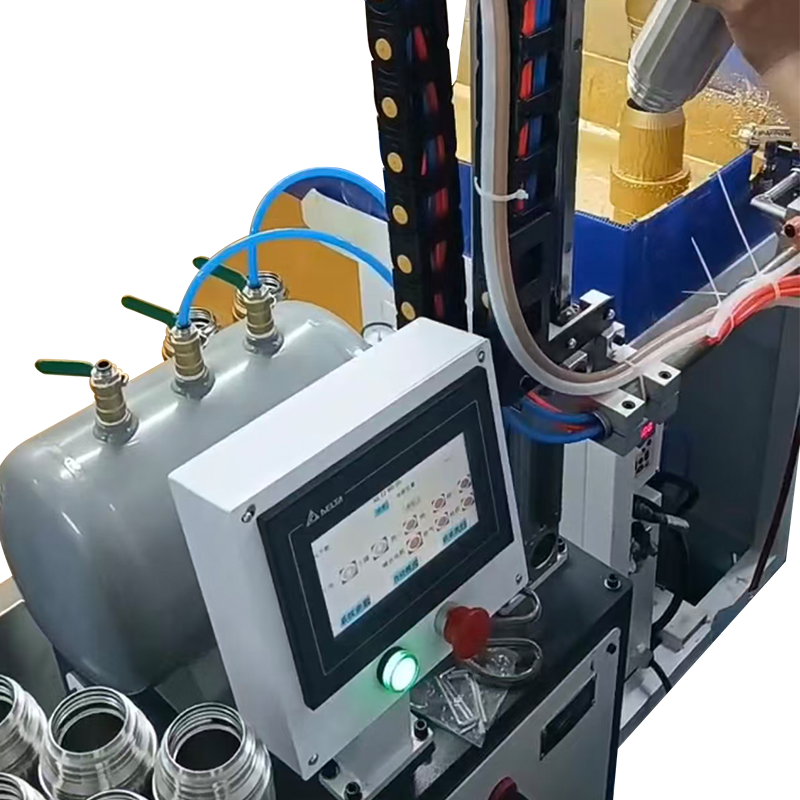

The CNC Rim Neck Cutting Machine is a high-precision, fully automated equipment designed for cutting and trimming the waste material at the mouth of cups and pots.

Product Features:

PLC Integrated Operation Control:

The machine adopts a PLC control system with an intuitive interface and knob switch design. The function keys are clearly marked for easy operation.High Precision Linear Guide:

Equipped with an HGH25 linear slide, the machine offers excellent rigidity and smooth motion, ensuring consistent cutting accuracy and long-term stability during high-speed operation.Versatile Functionality:

The system supports dual applications for edge cutting and shrink waterproof neck trimming, providing strong adaptability to various cup and pot materials.Precision Spindle Assembly:

The cast spindle sleeve ensures exceptional coaxiality within 0.01mm, minimizing vibration and ensuring high cutting precision.User-Friendly Fixture Design:

The fixture is engineered for quick clamping and easy adjustment, significantly improving production efficiency and reducing setup time.High-Quality Cutting Blade:

The cutter is made of Cr12MOV tool steel, heat-treated to HRC58°–62°, providing superior hardness, wear resistance, and long service life. -

Specifications (Mpa)

Hydraulic(Min)

Productivity(KW)

Rated power(Kg)

Net weight(MM)

Overall dimensions0.5-0.8 14 1.3 395 850×1050×2300 -

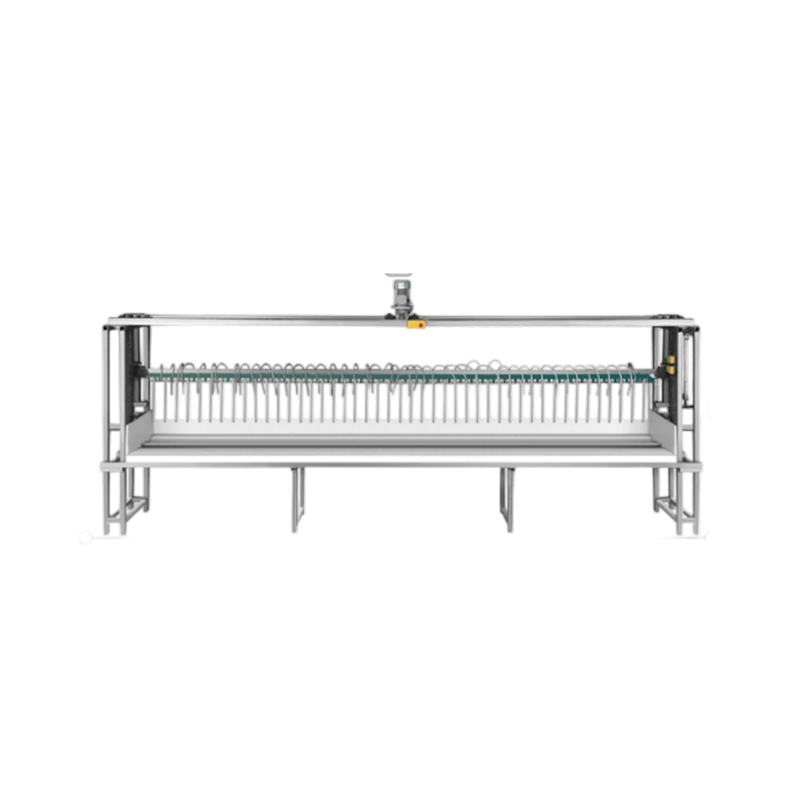

Water Rise

It uses ultra-high-pressure water as the power medium to expand and form straight or irregularly shaped tube blanks into complex profiles (such as drum, gourd, or curved shapes) that meet the design requirements.

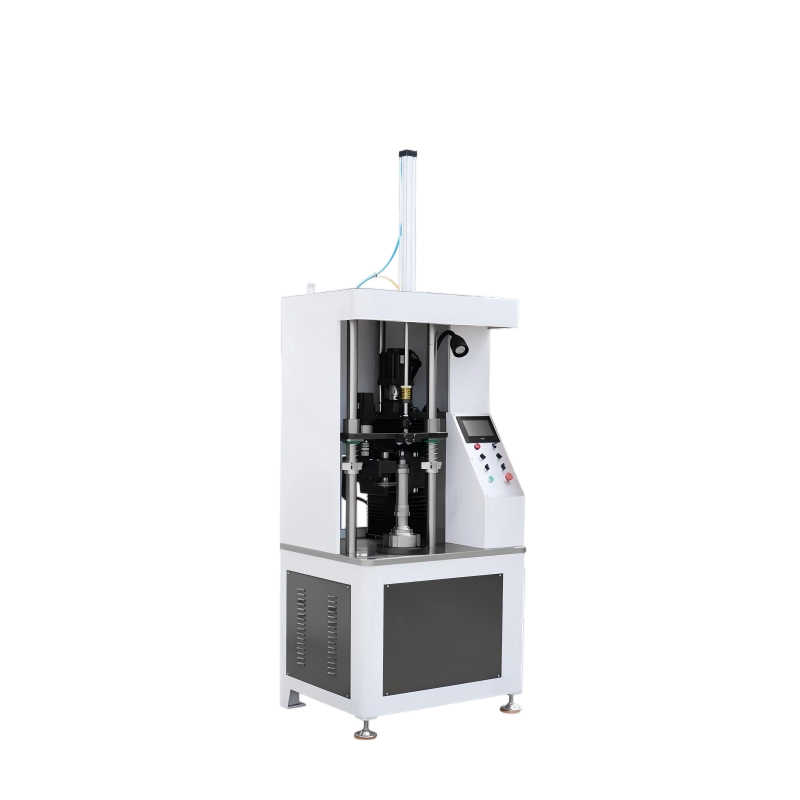

SegmentationIt involves cutting a long, semi-finished inner liner tube blank (e.g., after thinning) into two or shorter liners, thereby significantly improving material utilization and production efficiency.

English

English