We are proud to announce the official launch of the website for Yongkang Hubang Machinery Technology Co., Ltd.!

READ MORE-

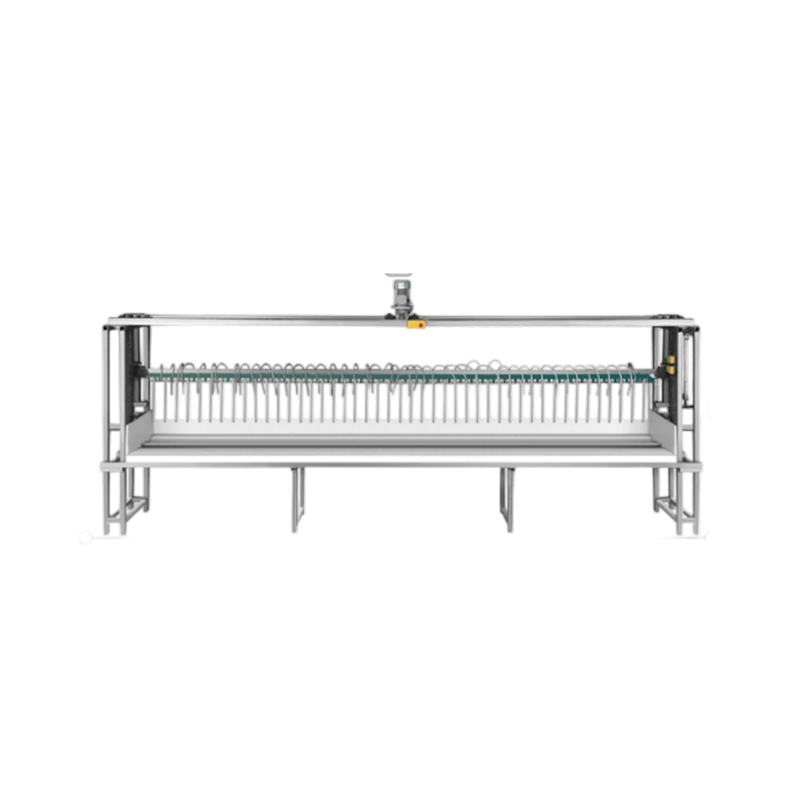

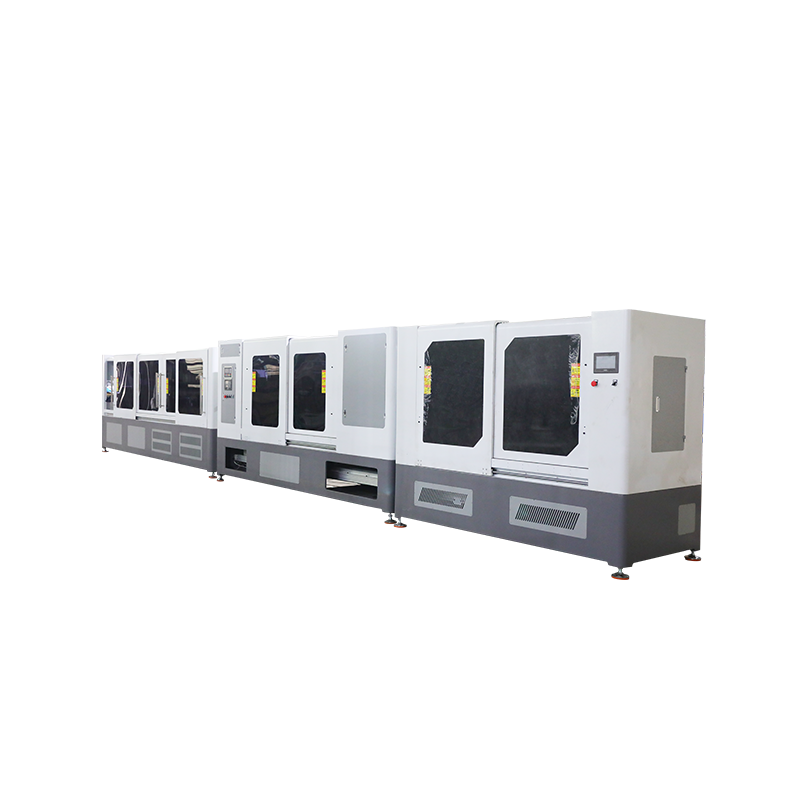

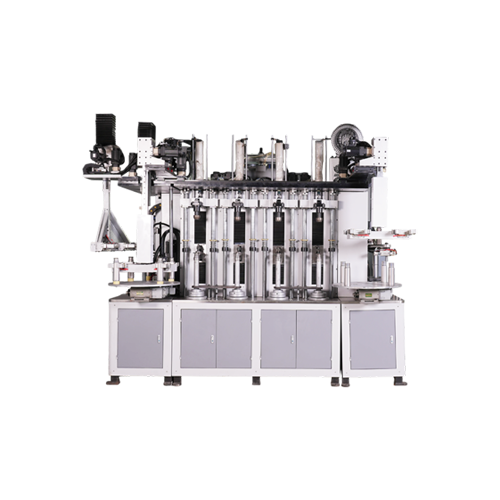

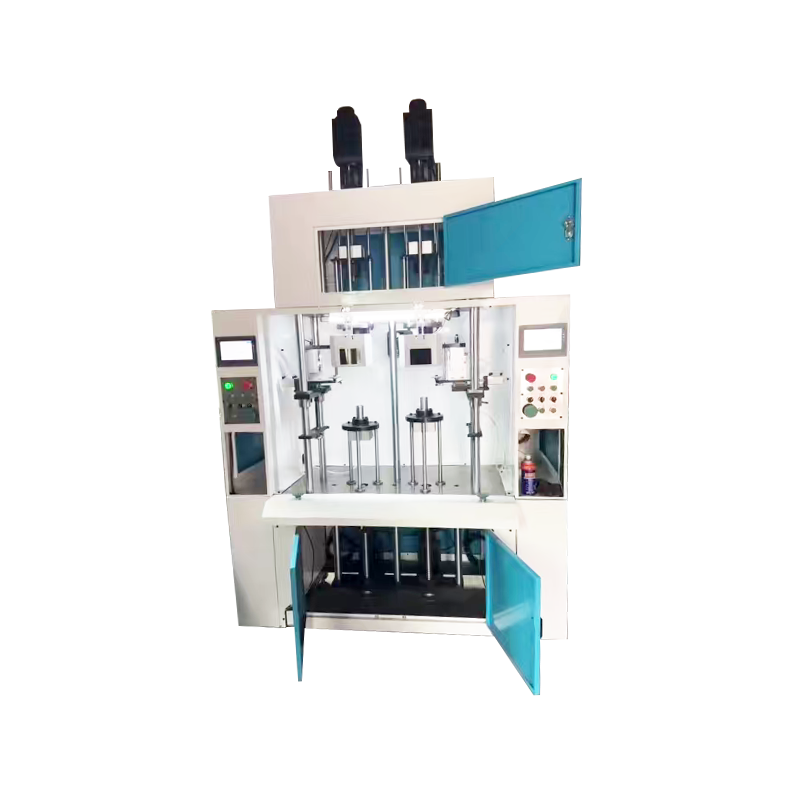

The Electrolysis Inner Wall Polishing Machine is made for internal surface finishing of stainless steel thermos cup liners and other metal containers. It efficiently removes internal stains, oxidation layers, and micro-corrosion, producing a smooth, bright, and hygienic inner surface.

Key Features:

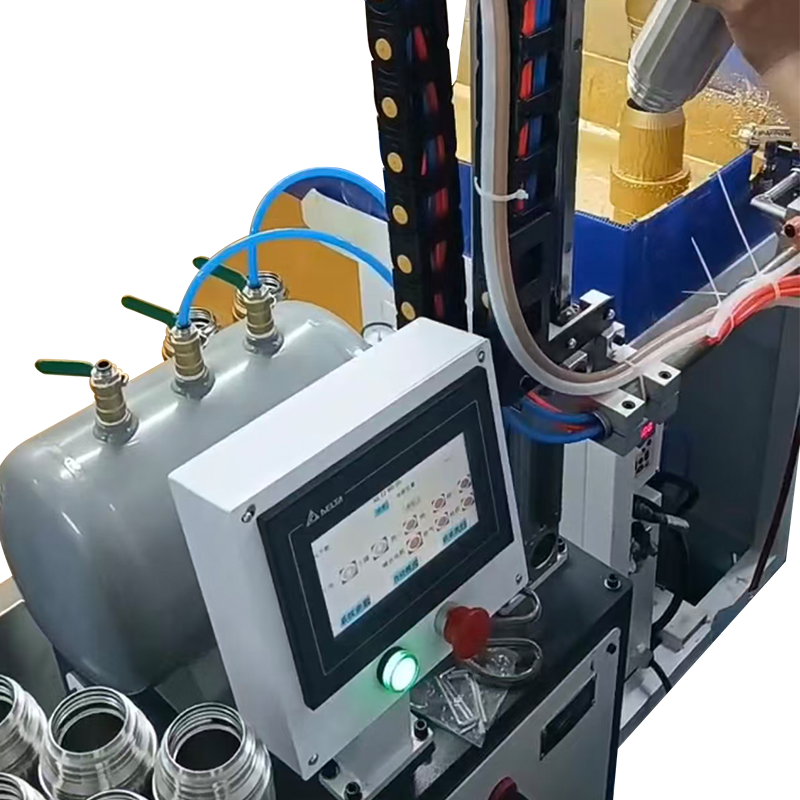

Electrolytic Polishing Technology: Utilizes a controlled chemical-electrolytic reaction to polish the inner wall of metal containers. This method enhances surface smoothness, improves corrosion resistance, and achieves a mirror-like finish without mechanical abrasion.

Multi-Station Operation: Equipped with 45 acid injection stations, the machine enables simultaneous processing of multiple liners. The up-and-down motion of each station is precisely controlled for consistent polishing quality across all units.

Adjustable Stroke Mechanism: Driven by a turbine reducer motor, the travel distance is adjustable to accommodate thermos cups of various heights, providing flexibility for different product sizes.

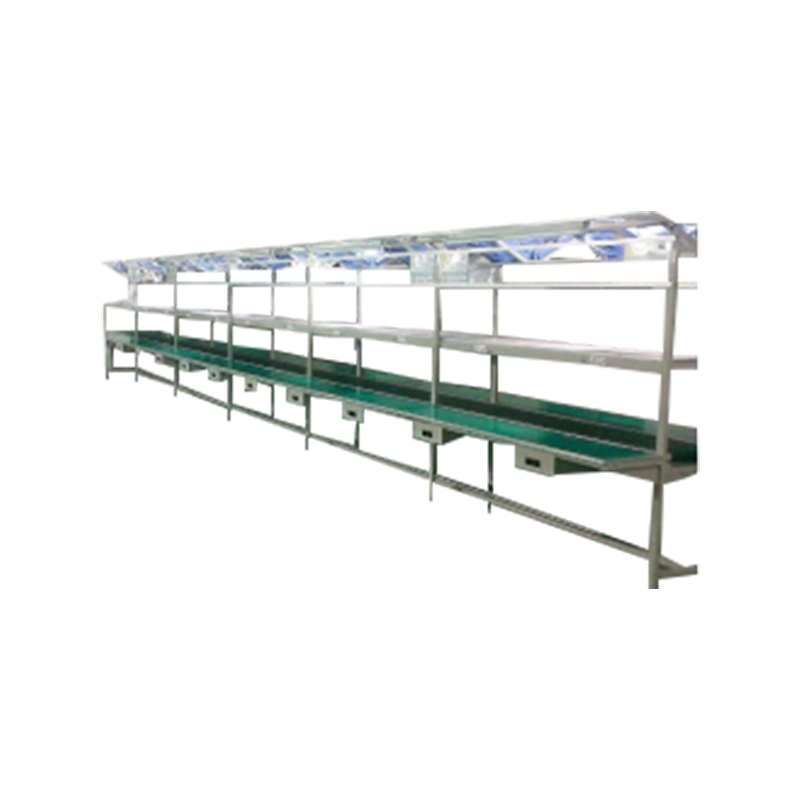

High Productivity and Ease of Use: Features a manual continuous feeding system that allows operators to achieve high output efficiently.

Durable and Stable Construction: Built from corrosion-resistant materials with a robust framework, the machine guarantees long-term reliability and stable performance in industrial environments.

-

(Min)

Productivity(KW)

Rated power(Kg)

Net weight(MM)

Overall dimensions20 4.0 635 6000×720×2100 -

Electrolysis

It utilizes electrochemical principles to perform micro-level etching and leveling on the surface of the stainless steel inner liner, making it extremely smooth and uniform while forming a chromium-rich passive film. This significantly enhances the product's corrosion resistance, cleanability, and aesthetic appeal.

English

English