We are proud to announce the official launch of the website for Yongkang Hubang Machinery Technology Co., Ltd.!

READ MORE-

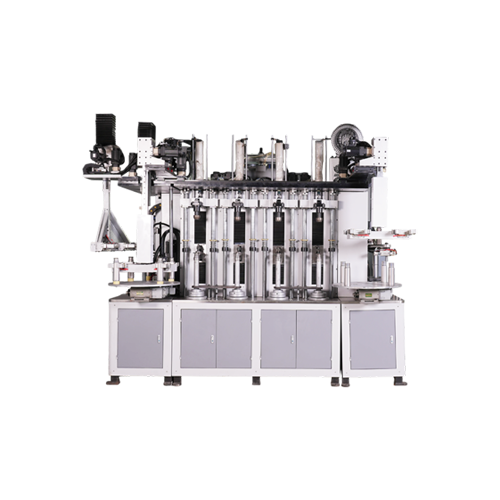

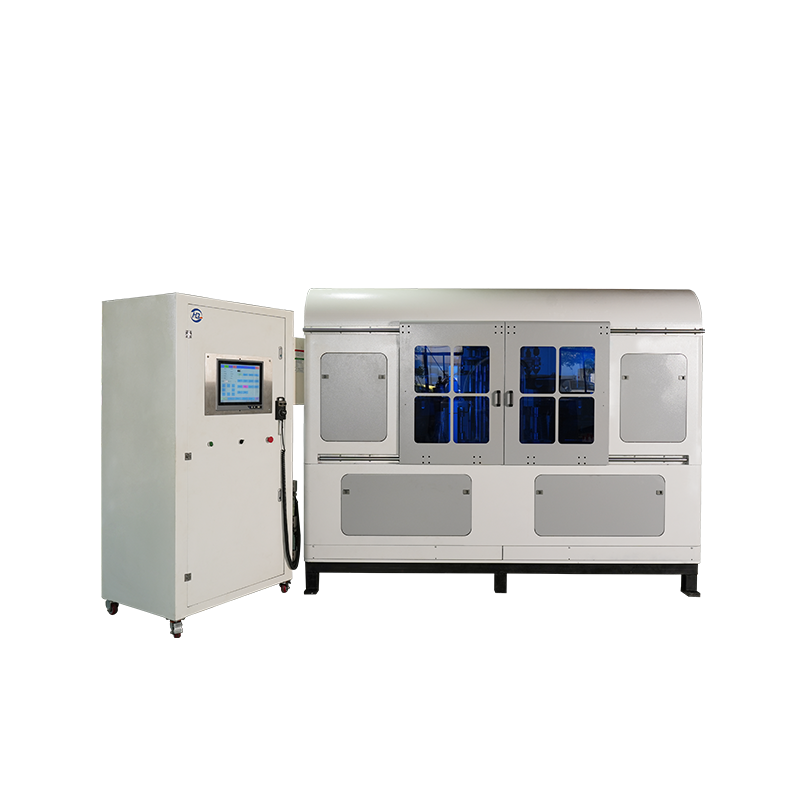

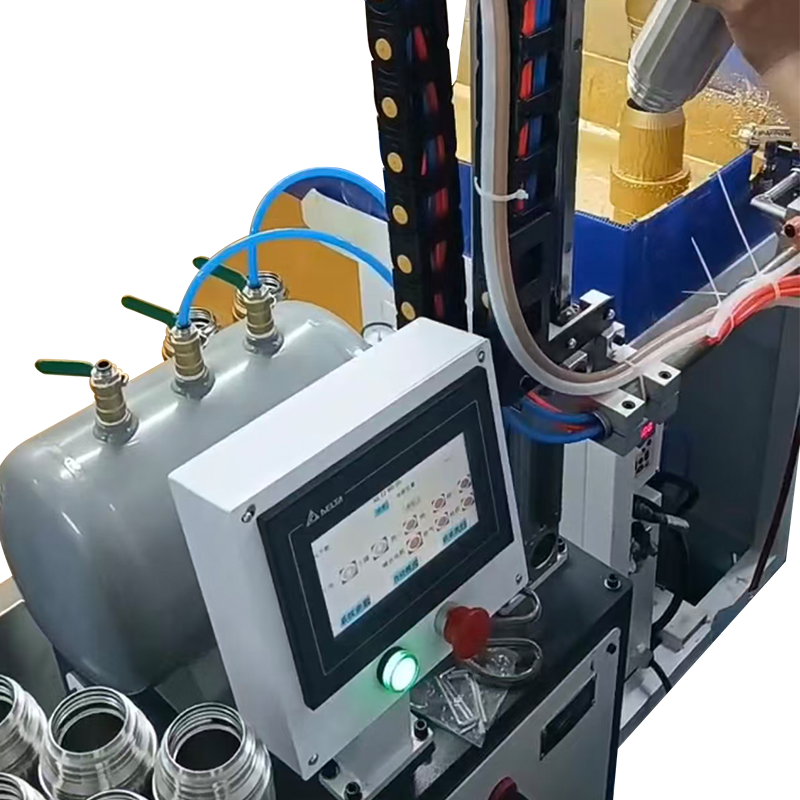

The 2 Stations Auto Laser Bottom Welding Machine is designed for automatic welding of flat-bottom and short-arc-bottom cups and pots. It adopts advanced laser technology combined with a dual-station structure to enhance productivity and maintain stable welding quality.

Product Features:

Dual-Station Design: The machine allows welding of two insulation cups simultaneously, significantly improving output and reducing idle time during production.

Rotational Welding Mechanism: Utilizes the principle of spindle rotation to drive the cup body, achieving uniform and stable welding along the circular arc bottom.

High Precision Laser System: Ensures consistent weld seams with smooth, firm joints, reducing deformation and improving the appearance of the final product.

Automated Control: The fully automatic process minimizes manual intervention, reducing human error and ensuring uniform product quality across batches.

Application Range: Suitable for stainless steel insulation cups, pots, and other round-bottom containers used in the thermal and household product manufacturing industry.

Production Efficiency: Designed for continuous operation, this machine delivers high-speed performance while maintaining precision and reliability in large-scale manufacturing environments.

-

Specifications (Mpa)

Hydraulic(Min)

Productivity(KW)

Rated power(Kg)

Net weight(MM)

Overall dimensions0.4-0.6 12 0.6 350 1150×1000×2250 -

Backing

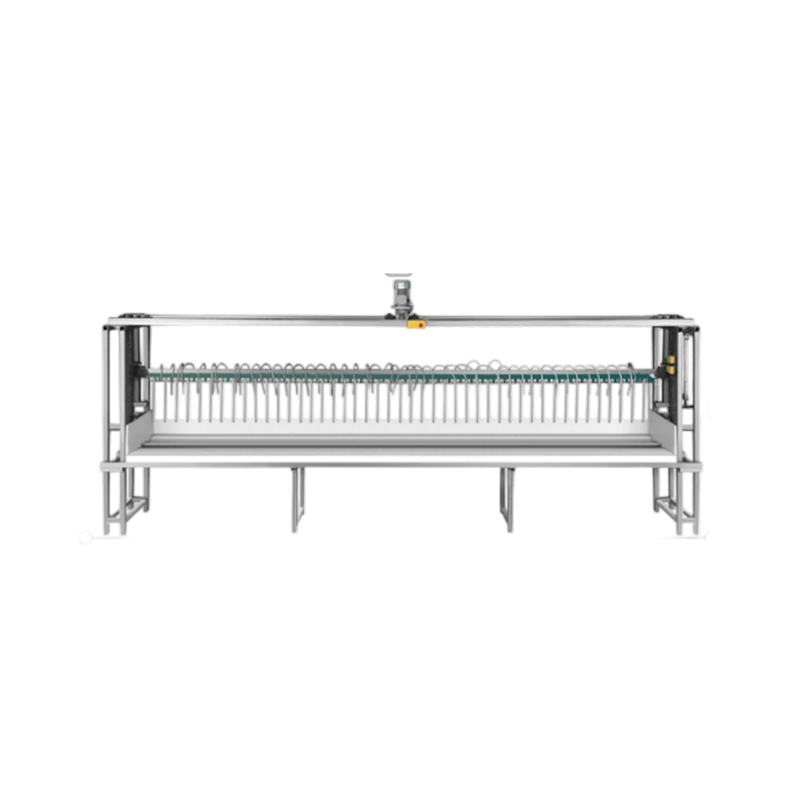

Following vacuum evacuation, it permanently and hermetically seals the pumping port, thereby trapping the vacuum within the inter-shell cavity to achieve lasting thermal insulation performance.

English

English