We are proud to announce the official launch of the website for Yongkang Hubang Machinery Technology Co., Ltd.!

READ MORE-

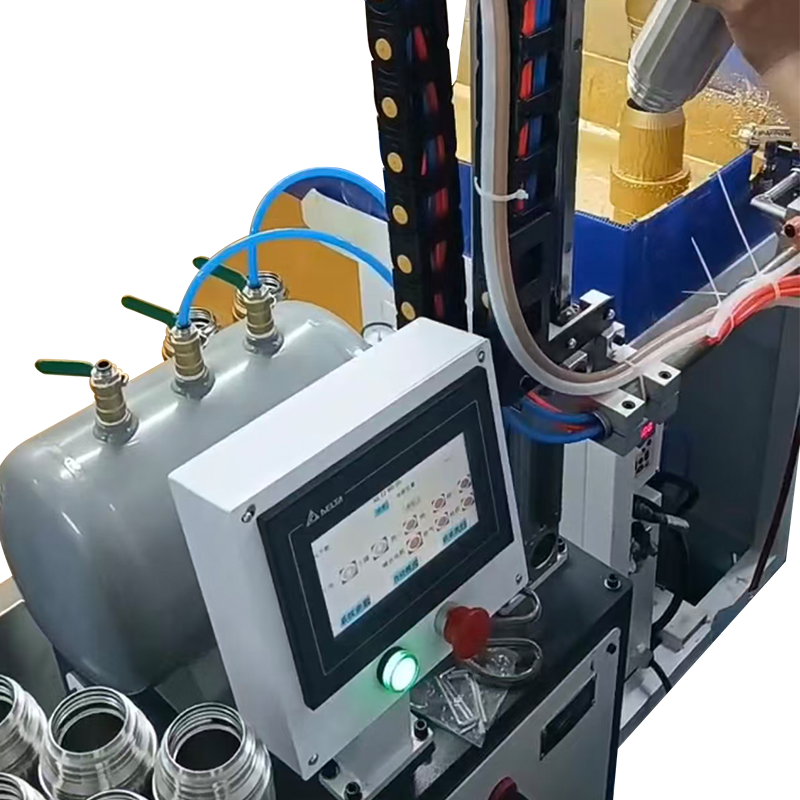

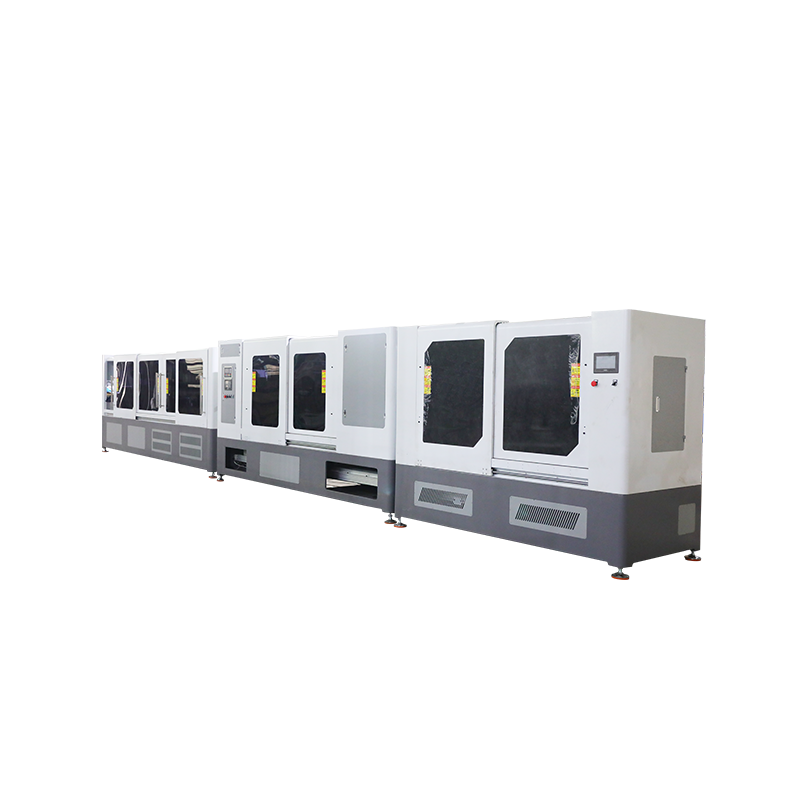

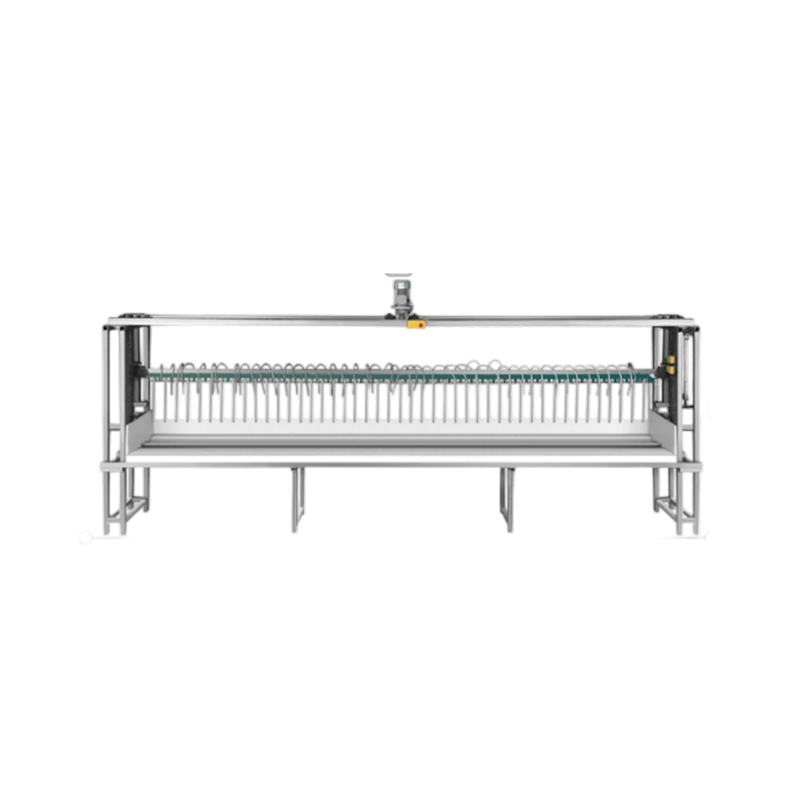

The Powder Coating Spray Painting Machine for Bottles is specifically designed for the uniform and efficient coating of stainless steel bottles, ensuring a high-quality finish with excellent adhesion and durability.

Key Features and Advantages:

Advanced Control System: Equipped with an industrial-grade control system, the machine allows precise adjustment of spray parameters such as voltage, powder flow, and speed.

Uniform Coating: Utilizing electrostatic powder spraying technology, the machine ensures even powder distribution across the bottle surface, reducing material waste and improving finish quality.

High Production Efficiency: The machine supports continuous operation with a multi-station conveyor system, capable of handling multiple bottles simultaneously, enhancing throughput and minimizing downtime.

Flexible Application: Quick-change fixtures and adjustable spraying arms allow the machine to accommodate different bottle sizes and shapes, making it suitable for a wide range of production requirements.

Durable and Reliable Construction: The machine is built with a robust frame and precision components, ensuring long-term stability, low maintenance, and reliable operation under heavy production conditions.

-

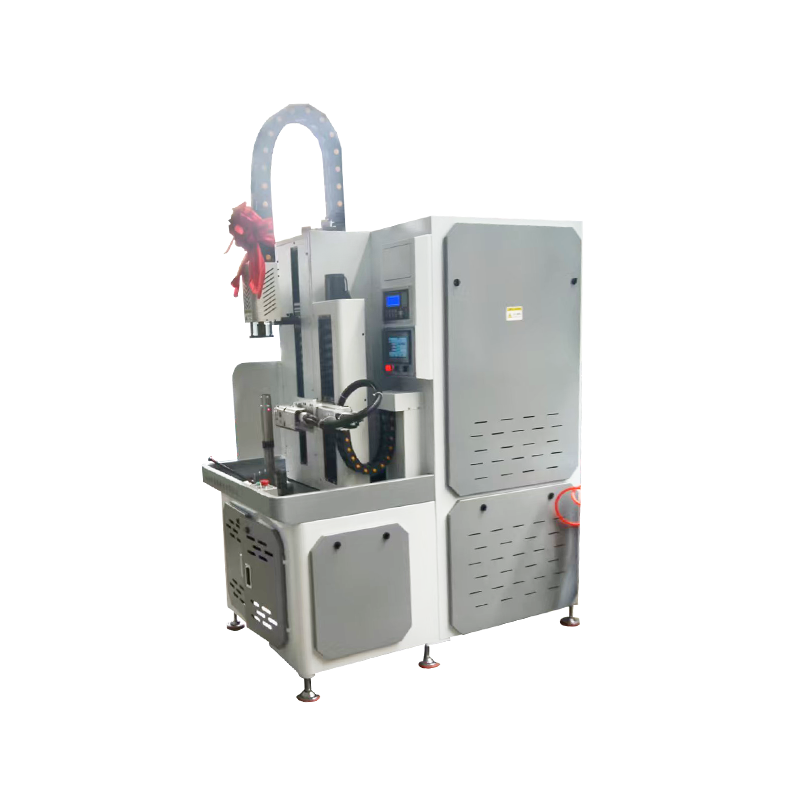

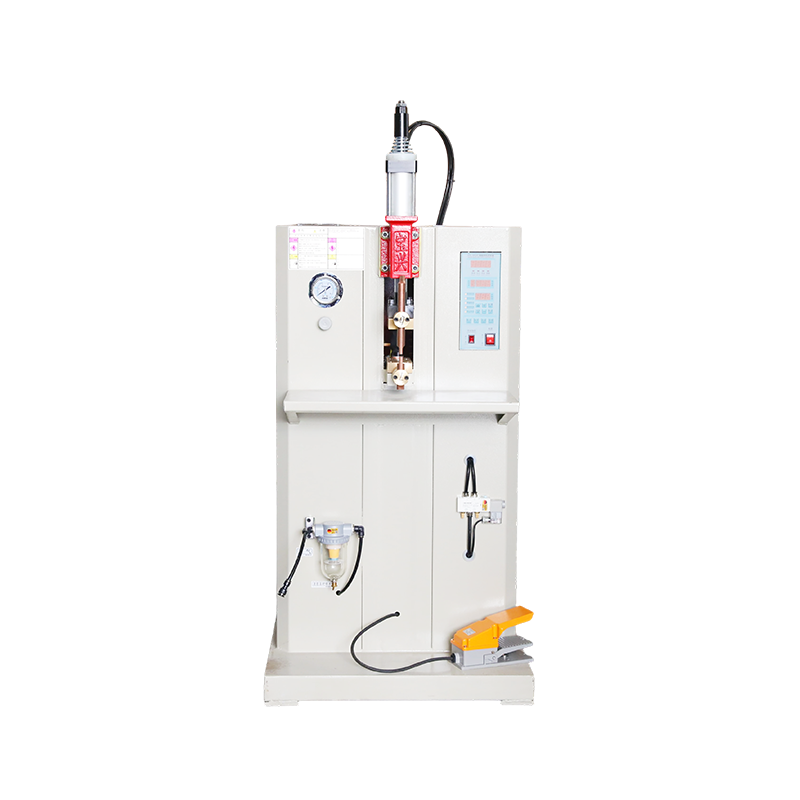

Painting reciprocating machine Voltage: Power: Weight: Packaging dimensions: 220V 0.8kW 80kg 650mm × 500mm × 1750mm Painting rotary table Voltage: Power: Weight: Packaging dimensions: 220V 0.55kW 40kg 550mm × 600mm × 1000mm Dual-Station Tape Wrapping Machine Voltage: Power: Weight: Packaging Dimensions: 220V 0.79kW 300kg 1000mm × 700mm × 1700mm -

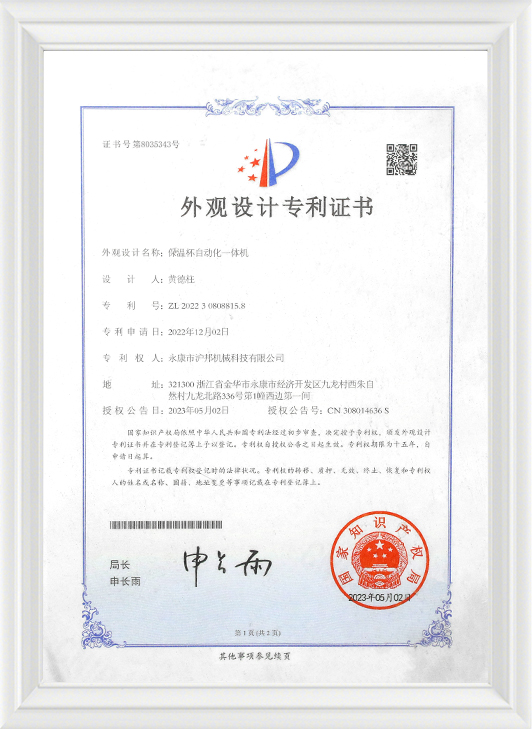

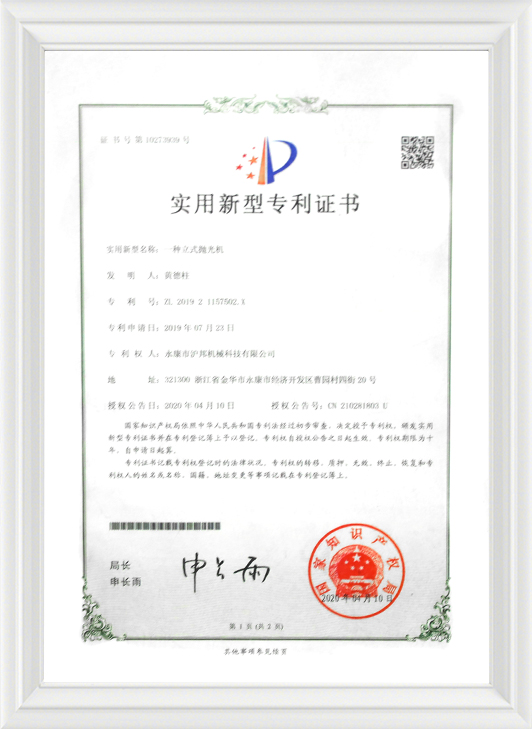

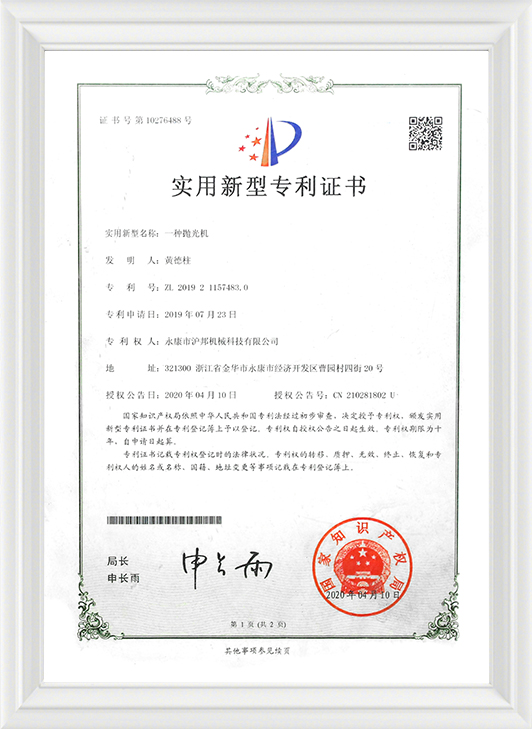

Appearance Treatment

It employs a spectrum of physical and chemical methods to bestow the product with its final market-ready appearance, protecting the substrate while simultaneously achieving aesthetic premiumization and functional enhancement.

English

English