We are proud to announce the official launch of the website for Yongkang Hubang Machinery Technology Co., Ltd.!

READ MORE-

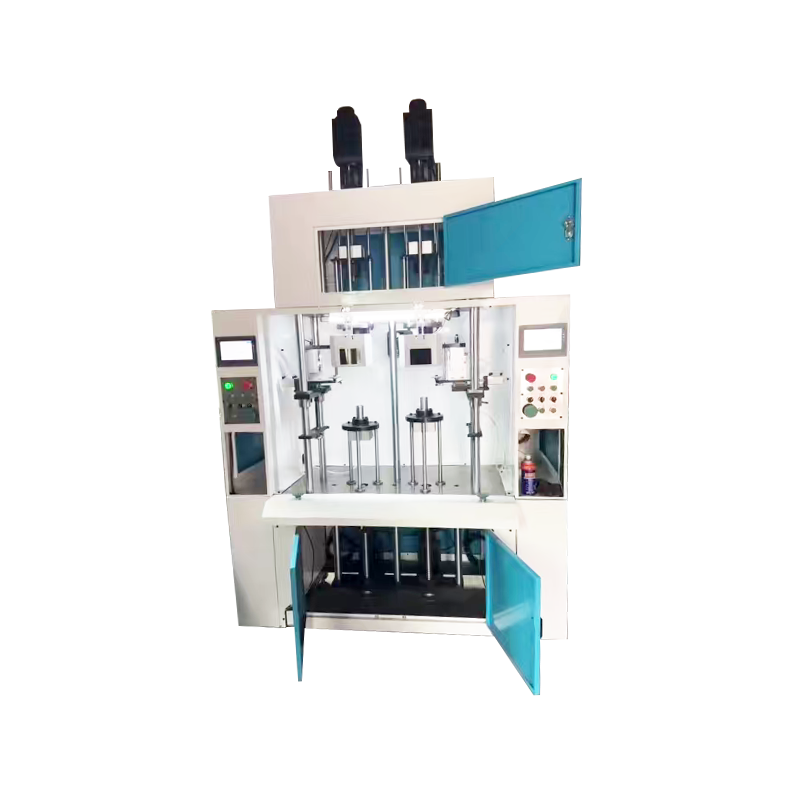

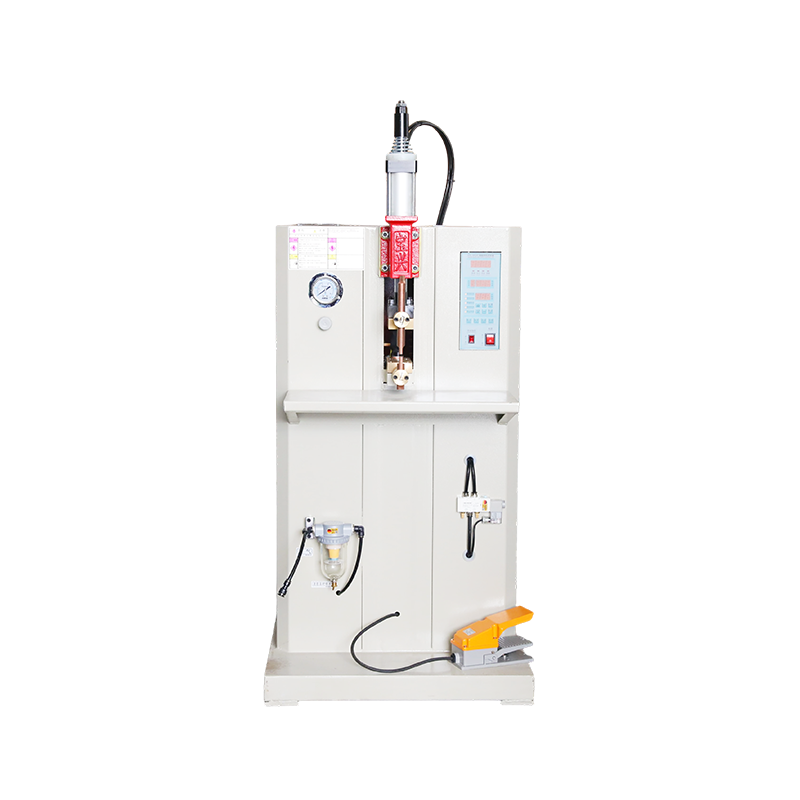

The Water Bulging Bottle Making Machine is made for the precision forming process of both the outer shell and inner liner of cup pots or similar containers. It ensures stable operation, efficient forming cycles, and consistent product quality.

Product Features

Servo Motor Drive: The main motor adopts a high-performance servo motor, offering high starting torque, low noise, long service life, and reduced energy consumption.

Vertical Structure: The equipment features a vertical design that enhances mold opening and overall height, optimizing space utilization. Customization options are available based on specific customer production needs.

PLC Touch Screen Control: The system uses an advanced PLC with a touch screen interface, allowing for intuitive operation, precise parameter settings, and reliable process monitoring.

Rapid Low-Pressure Injection System: Equipped with an independent rapid low-pressure injection system that efficiently exhausts air from the mold cavity during the cylinder’s downward stroke. This is followed by filling with bulging liquid to create a low-pressure liquid chamber, allowing the supercharger to inject high-pressure liquid quickly and reduce the forming cycle time.

-

Specifications (Kn)

Nominal foroe of master cyinder(Mpa)

Masmum working pressureof master cyinder(MM)

Master cylinder stroke(MM)

Slide area1250 20 750 600x530 (MM)

Booster cyinder stroke(Mpa)

Maximum pressure of water cylinder(KW)

Motor power(MM)

Overall dimensions(Kg)

Machine weight350 40-60 18.5+2.2 2660x188x3500 6500 -

Water Rise

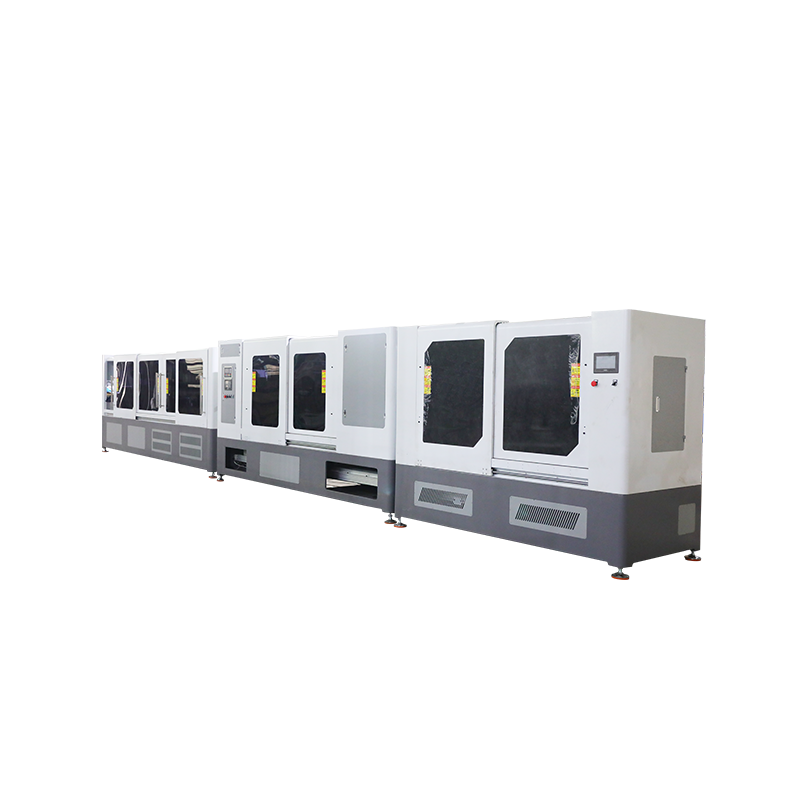

It uses ultra-high-pressure water as the power medium to expand and form straight or irregularly shaped tube blanks into complex profiles (such as drum, gourd, or curved shapes) that meet the design requirements.

Water RiseIt utilizes ultra-high-pressure water to perform precise expansion on the pre-thinned, cylindrical inner liner blank, causing its external contour to perfectly conform to the inner wall of the outer shell and optimizing the base shape, thereby creating optimal conditions for subsequent vacuum evacuation and sealing.

English

English