We are proud to announce the official launch of the website for Yongkang Hubang Machinery Technology Co., Ltd.!

READ MORE-

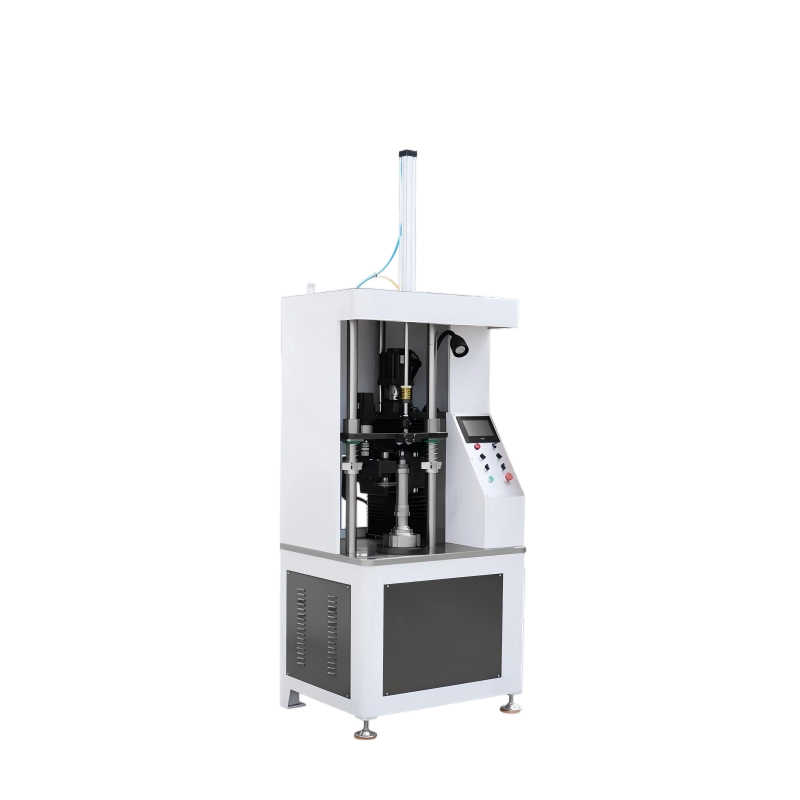

The Vacuum Getter Machine is a specialized equipment designed for drawing air out of insulated thermos containers, followed by precise heating and sealing of the outlet. It ensures efficient degassing and vacuum creation, which are critical steps in the production of high-quality vacuum-insulated bottles and flasks.

Product Features:

Advanced Control System: Equipped with a PLC and touch screen man-machine interface for intelligent control. The system provides real-time monitoring of vacuum levels, heating conditions, and operation status.

High Vacuum Protection: Effectively prevents oil oxidation and oil backflow from the diffusion pump, ensuring stable vacuum performance and extending equipment lifespan.

Double Station Design: Utilizes stainless steel vacuum chambers to perform simultaneous degassing of double containers, improving production efficiency and consistency.

High Efficiency: Guarantees a fast degassing process with optimized heating performance, resulting in superior vacuum sealing quality.

User-Friendly Interface: The touch screen displays the workflow, operational status, and error messages, with automatic fault detection and protection functions.

Flexible Operation: Supports both automatic and manual operation modes, suitable for different production needs such as cryogenic vessel degassing, leak detection, and vacuum system testing.

Easy Maintenance: Modular design simplifies maintenance and enhances system reliability during continuous production.

-

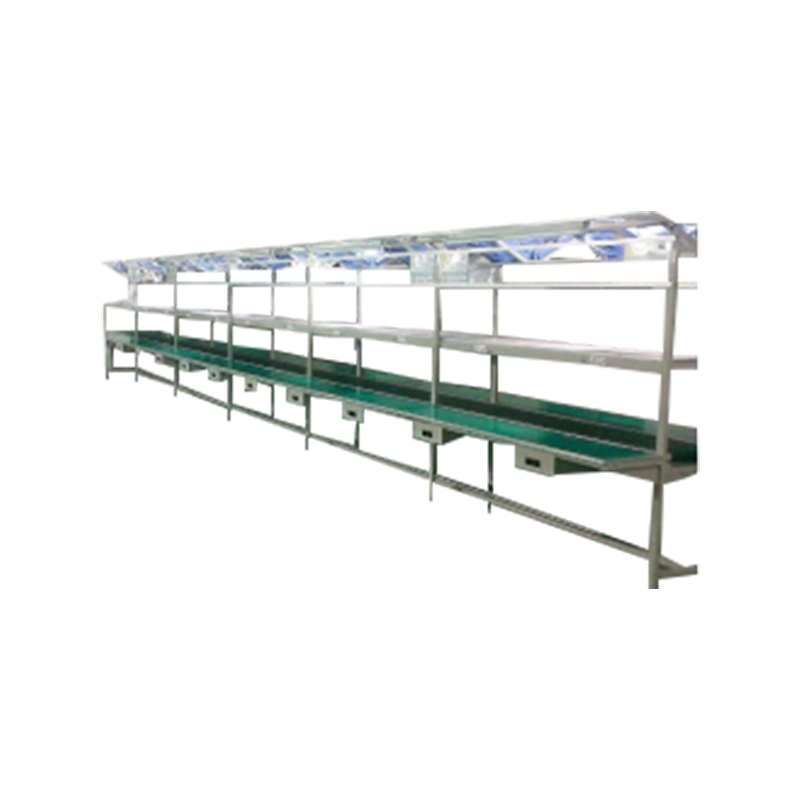

Specifcations (MM)

Biliary size in vacuum chamber(H)

Production efficiency(V)

Rated power(V)

Rated powerDiameter 1800 × 1300 Dimensions can be customised to client specifications Double-chamber oven, capacity approximately 1250 items (350–1000 ml) 380 120 (Kg)

Net weight(MM)

Overall dimensionsWorking vacuum Maximum heating temperature 3 5500x1300x3000 (Cooling to 400°C) ≤5×10⁻3 Pa ≤580 -

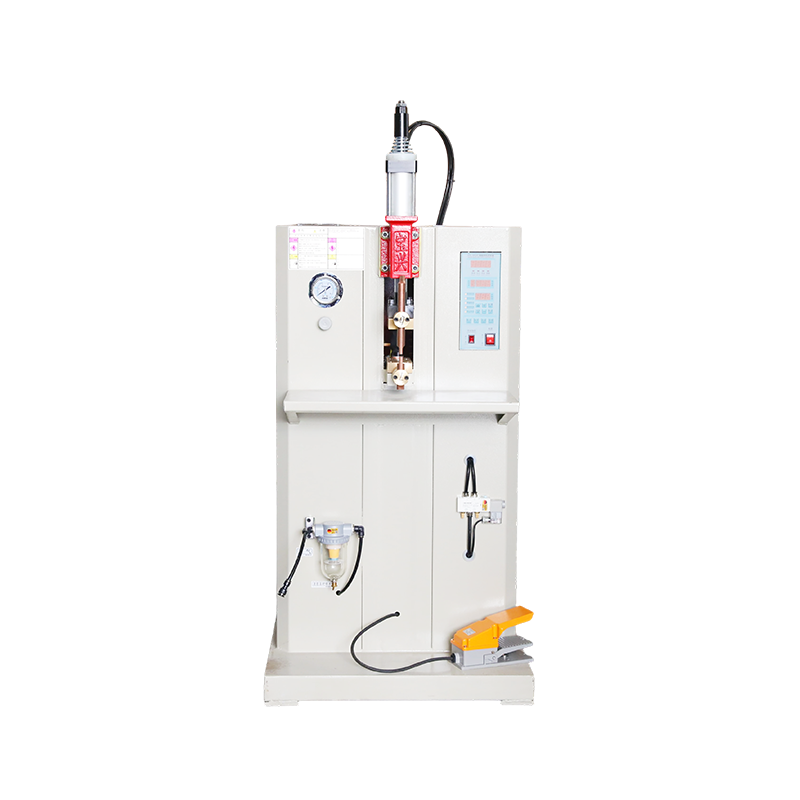

Backing

Following vacuum evacuation, it permanently and hermetically seals the pumping port, thereby trapping the vacuum within the inter-shell cavity to achieve lasting thermal insulation performance.

English

English