We are proud to announce the official launch of the website for Yongkang Hubang Machinery Technology Co., Ltd.!

READ MORE-

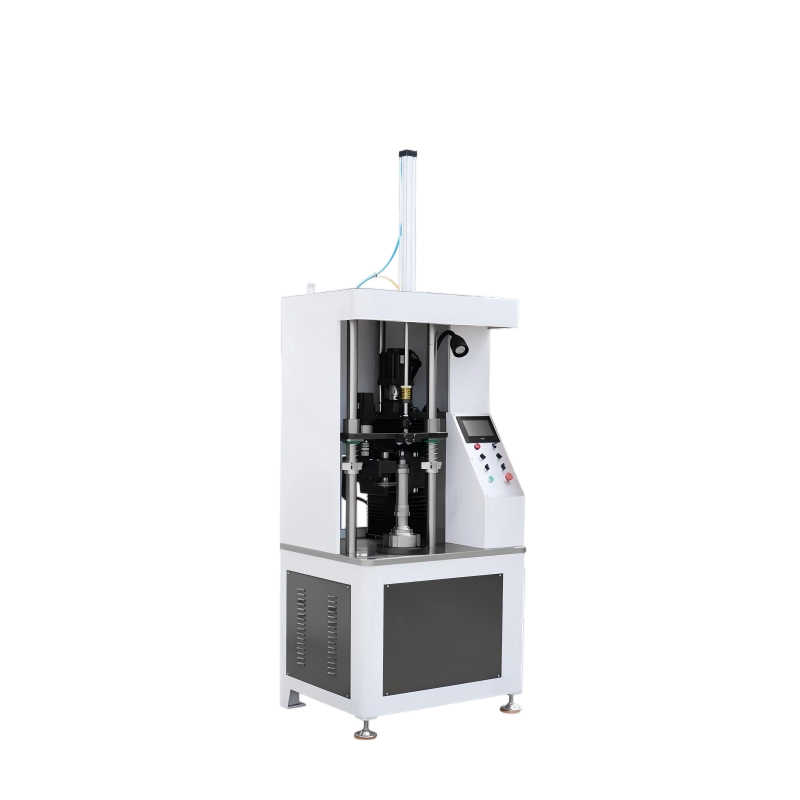

The Bottle Flask Top & Bottom Edge Trimming Machine is a precision processing equipment designed for the accurate machining of thermos flask edges.

Product Features:

Dual-End Machining Efficiency:

The machine can process both the mouth and the bottom of the thermos bottle simultaneously in one clamping operation. This increases machining efficiency and ensures consistent alignment and precision across both ends.Frequency-Controlled Spindle Motor:

The spindle motor is driven by a frequency converter, allowing smooth torque adjustment during start-up and stopping. This enhances operational safety, reduces mechanical stress, and maintains product dimensional accuracy throughout the process.Adjustable Speed & Extended Durability:

The spindle speed is easily adjusted via frequency control, enabling quick adaptation to varying material requirements. The spindle structure features effective sealing and dustproof protection, ensuring stable performance and a long service life.High Accuracy and Consistent Quality:

Through precise clamping and optimized motor control, the machine guarantees uniform trimming results, providing smooth and accurate top and bottom edges for subsequent assembly or polishing processes. -

Product Structure Model: Equipment structure: Color Ratio: Total quality: Rated power: Overall dimensions: H23B-8123 Vertical Main white with orange 1118.5KG 6Kw L*W*H1400*1030*1950 Product Parameters Production efficiency: Operating System: 8Min Kunlun Tongtai -

Flat Mouth, Flat Bottom

This involves machining both the opening and the base of the cup body to achieve a flat, smooth finish that is perpendicular to the central axis, thereby ensuring the product's core functionality and quality.

Flat Mouth, Flat BottomIt establishes the foundation for the product's vacuum seal, structural stability, and hygienic safety through precision machining of both ends of the inner liner.

English

English