We are proud to announce the official launch of the website for Yongkang Hubang Machinery Technology Co., Ltd.!

READ MORE-

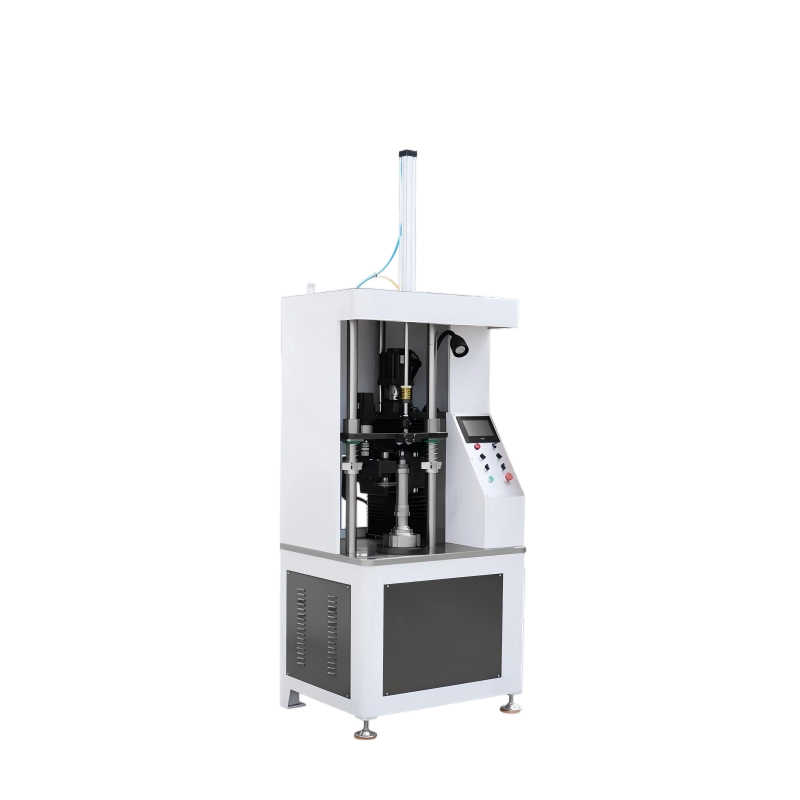

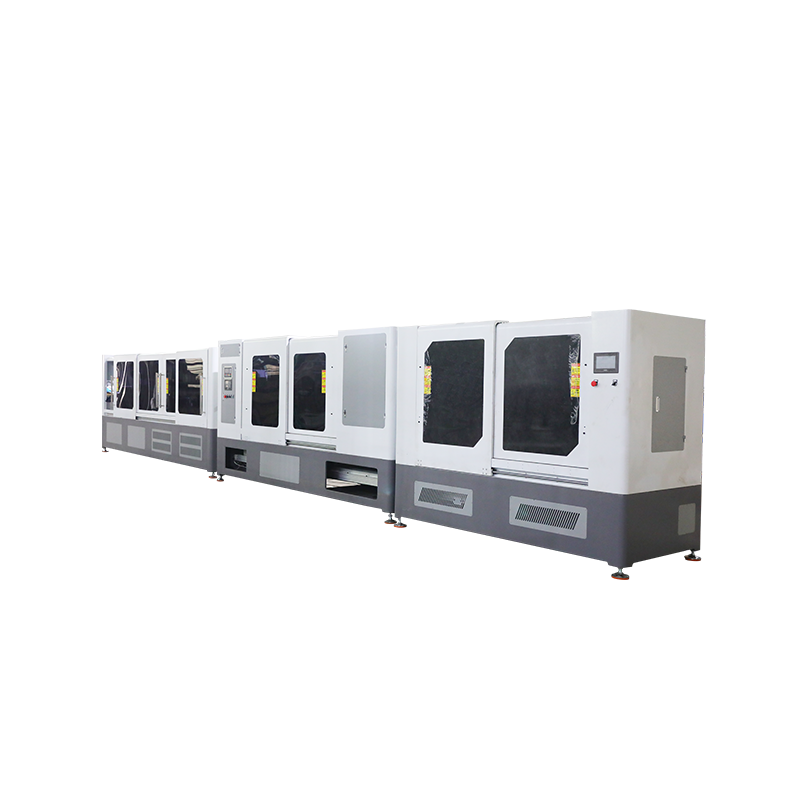

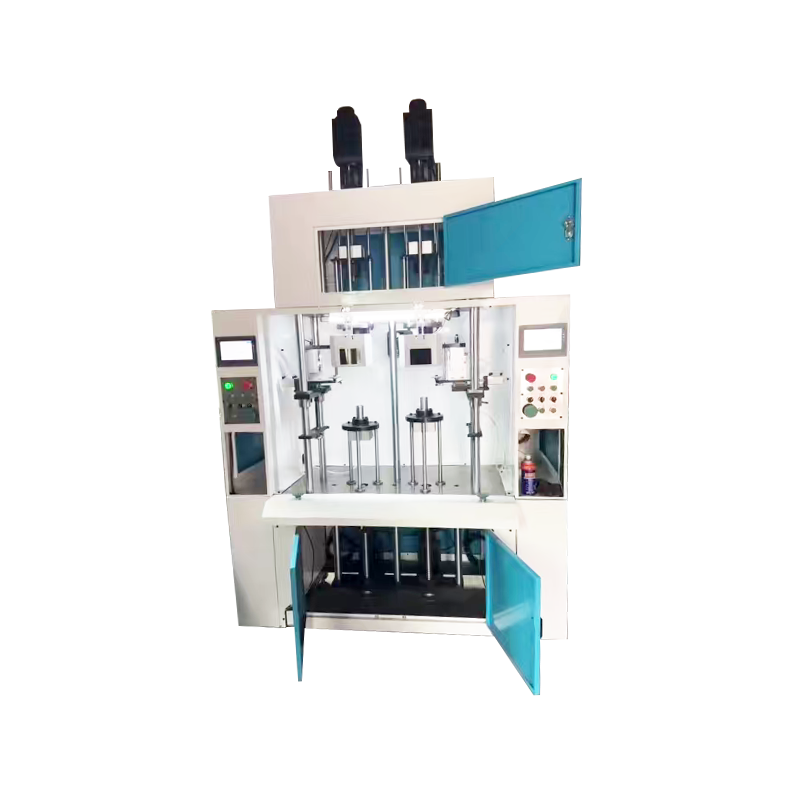

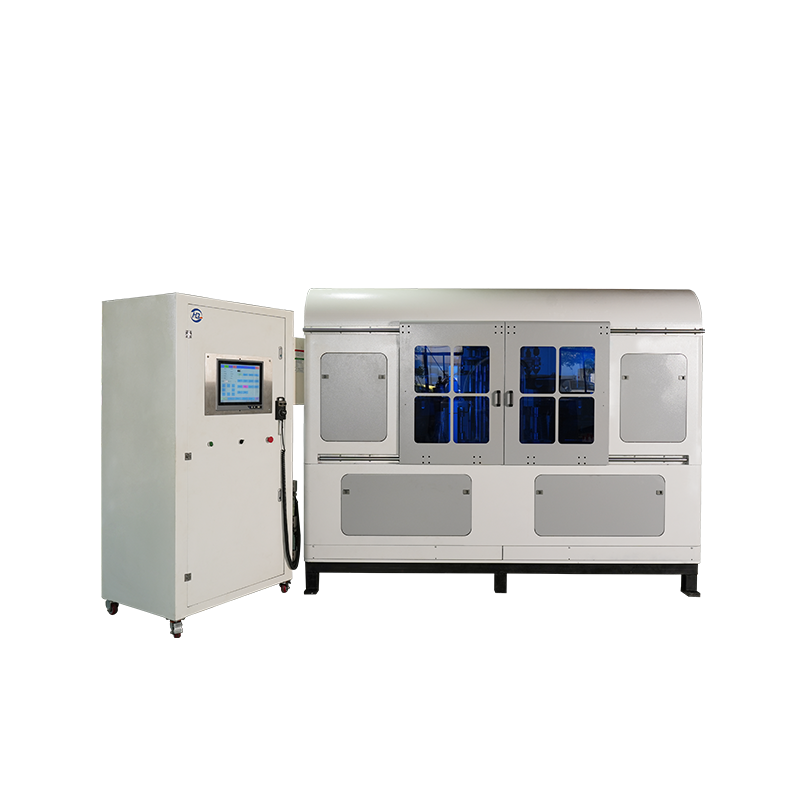

The 3-Axis Vertical CNC Screw Threading Machine is a high-precision, intelligent equipment designed specifically for the screw rolling process of Cup Pot Shell Mouths.

Main Features:

Advanced Control System

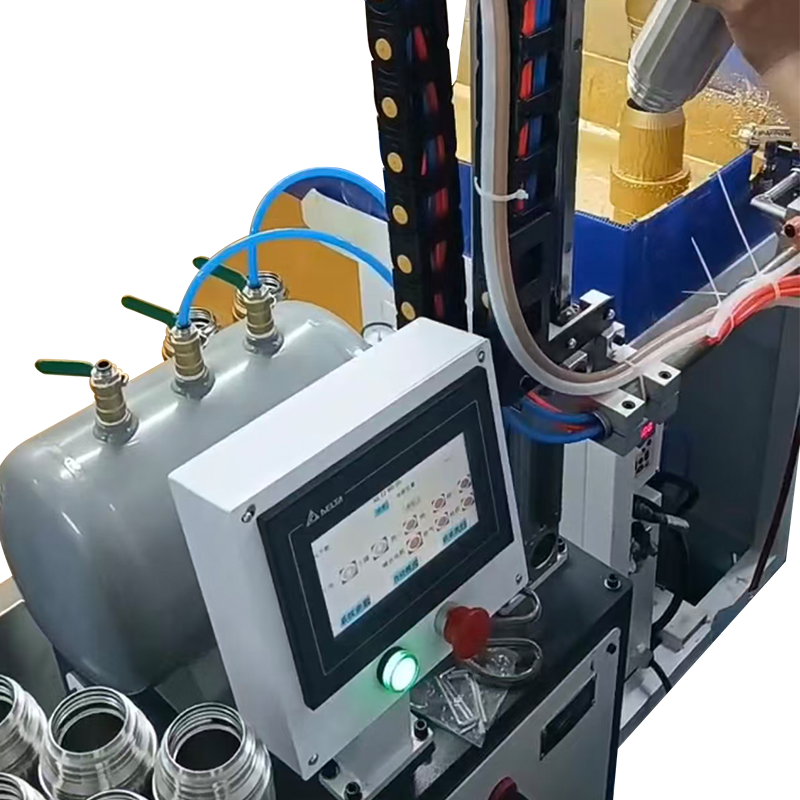

Equipped with a PLC touch screen human-machine interface, this machine offers intuitive operation, real-time monitoring, and flexible parameter adjustment.High Precision & Strong Adaptability

The system adopts three-axis servo motors combined with precision reducers, providing smooth transmission, high positioning accuracy, and excellent synchronization. It supports multi-angle and variable-speed operations for diverse threading requirements.Wide Processing Range

Designed to handle workpieces with diameters Φ20–Φ120mm and wall thicknesses between 0.1–0.8mm, this machine maintains dimensional accuracy and consistent thread quality across various materials.Adjustable Transmission System

The transmission mold shaft can be flexibly adjusted from 1:1 to 1:10, allowing the operator to adapt the machine for different rolling speeds and product characteristics.Robust Structural Design

Built with an integrated steel frame and an upper cylinder guide plate that covers the main shaft, the structure ensures vibration resistance, durability, and improved thread rolling accuracy.Enhanced Efficiency and Stability

With its vertical layout and optimized mechanical configuration, the machine delivers uniform thread forming, extended mold life, and stable long-term operation. -

Specifications (Mpa)

Hydraulic(Min)

Productivity(KW)

Rated power(Kg)

Net weight(MM)

Overall dimensions0.4-0.6 7 5.0 650 940×750×2500 -

Roll Size Thread

It roll-forms precisely mated threads onto the cup opening and the lid (or lid retainer) to achieve reliable screwing and sealing between the lid and the cup body.

English

English