We are proud to announce the official launch of the website for Yongkang Hubang Machinery Technology Co., Ltd.!

READ MORE-

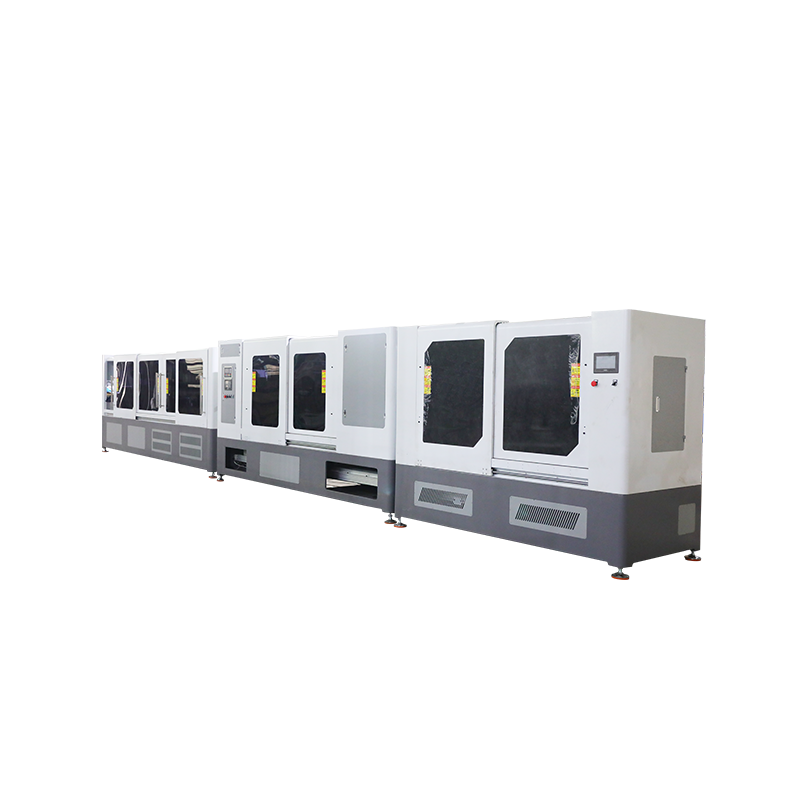

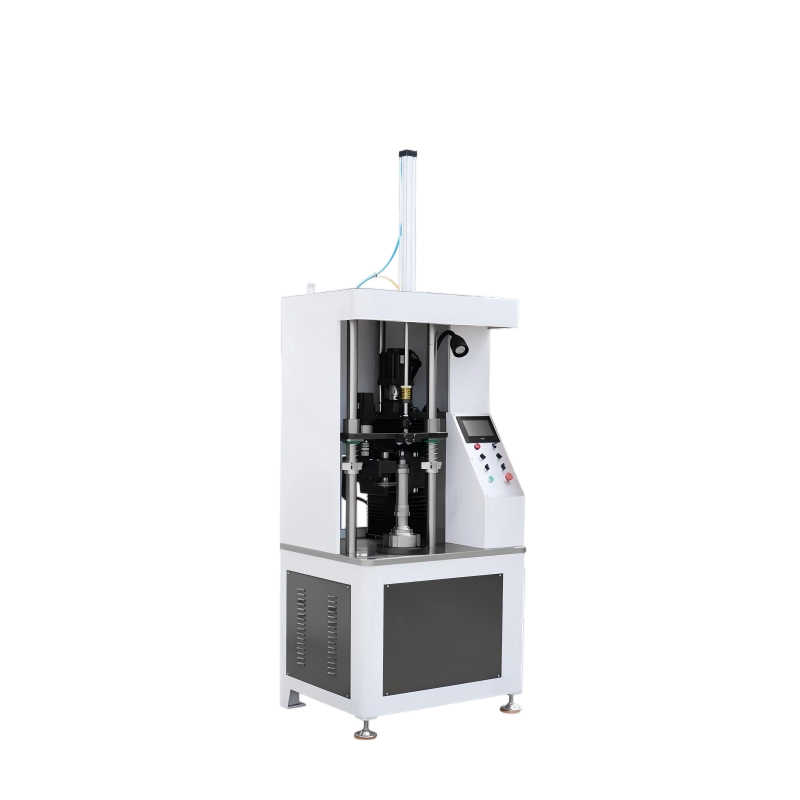

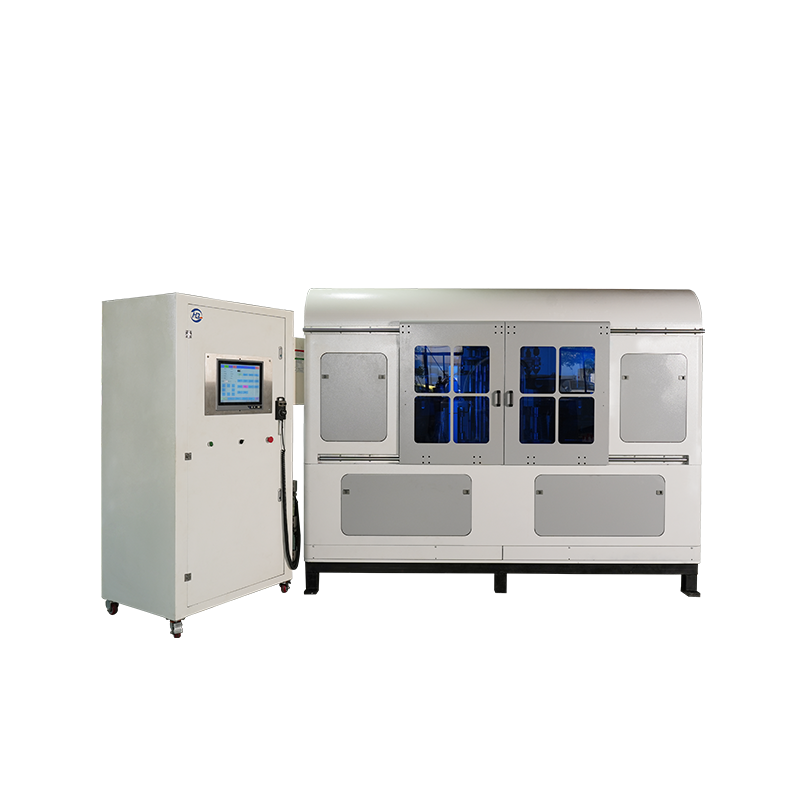

The Double Station CNC Tube End Shrinking Machine is designed for the spinning and compressing process of cup and pot mouths, ensuring precision forming and consistent results in metal processing applications.

Product Features

Main Structure:

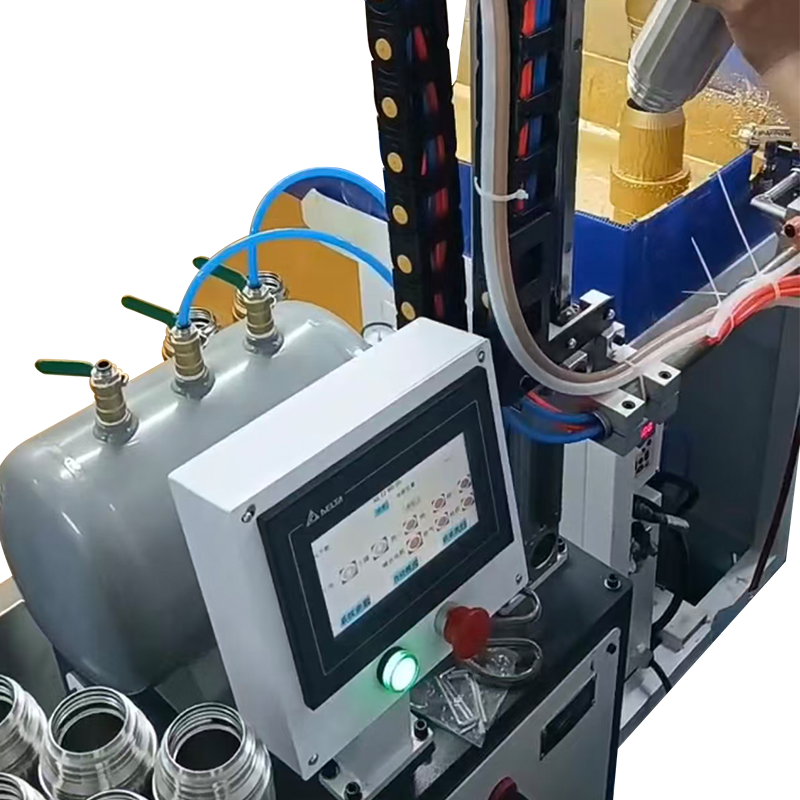

The machine body adopts an upgraded casting process for enhanced rigidity and stability. It uses high-quality systems and components sourced domestically and internationally, such as Wide CNC systems, Silver slides, and PS NSK bearings. These features ensure low vibration, minimal noise, and extended service life — more than twice that of conventional models.Lubrication and Maintenance:

Equipped with a lubrication monitoring system, the machine effectively extends the lifespan of the guide screws and ensures smooth, long-term operation.Spindle Control System:

The spindle section integrates a frequency conversion system, allowing stepless speed regulation and precise stopping functions. This enhances production efficiency and ensures operational safety.Dual-Station Design:

Featuring a dual-station configuration, the machine supports simultaneous operations, reducing labor costs, minimizing footprint, and significantly improving production efficiency. -

Specifications (Mpa)

Hydraulic(Min)

Productivity(KW)

Rated power(Kg)

Net weight(MM)

Overall dimensions0.5-0.8 16 8.0 2000 1450×900×2500 -

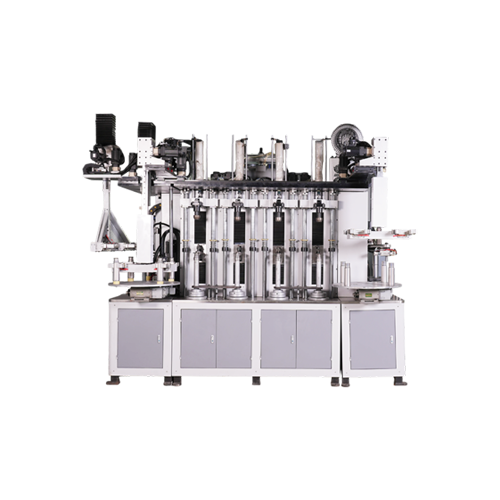

Necking

It reduces the diameter of one end of the cup body (typically the top opening) through localized compression, forming a specific stepped or tapered structure.

NeckingIt reduces the diameter of the liner's opening to create a stepped structure, which is used to precisely locate and support other components at the cup mouth (such as a sealing ring or evacuation tube). This is a critical step for ensuring vacuum integrity and structural stability.

English

English